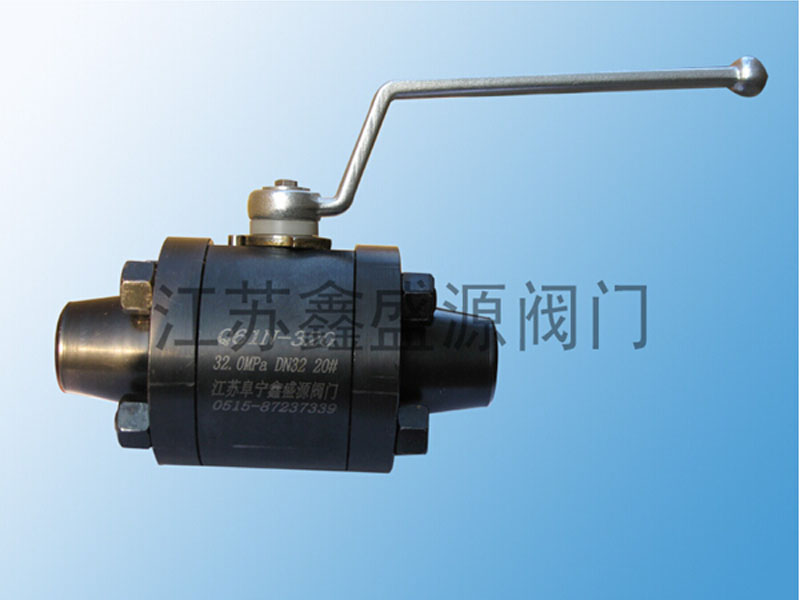

高压对焊球阀

商品详情

性能特点

技术参数

Q61N高压对焊球阀启闭件(球体)由阀杆带动,并绕阀杆的轴线作旋转运动的阀门。主要用于截断或接通管路中的介质,亦可用于流体的调节与控制,其中硬密封V型球阀其V型球芯与堆焊硬质合金的金属阀座之间具有很强的剪切力,特别适用于含纤维、微小固体颗料等介质。而多通球阀在管道上不仅可灵活控制介质的合流、分流、及流向的切换,同时也可关闭任一通道而使另外两个通道相连。高压对焊球阀阀门在管道中一般应当水平安装。Q61N高压对焊球阀它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。高压对焊球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。

Q61N高压对焊球阀适宜做开关、切断阀使用,高压对焊球阀的主要特点是本身结构紧凑,密封,结构简单,维修方便,密封面与球面常在闭合状态,不易被介质冲蚀,易于操作和维修,适用于水、溶剂、酸和天然气等一般工作介质,而且还适用于工作条件恶劣的介质,如氧气、过氧化氢、甲烷和乙烯等,在各行业得到广泛的应用。高压对焊球阀阀体可以是整体的,也可以是组合式的。

Q61N高压对焊球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻。

3.紧密稳定。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于高压对焊球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

Q61N高压对焊球阀特性:

公称压力:16-32MPa

适用温度范围:-20~232℃~350℃

适用介质:水、油、气及某些腐蚀性液体(W O G)

焊接类型:对焊(BW)、承接焊(SW)

Q61N高压对焊球阀主要零部件材料:

| 适用介质 | 型号 | 阀体 | 球体、阀杆 | 手柄 | 密封圈 | 垫片、填料 |

| 水、蒸汽、油品 | Q61N-160/320C | A105、45 | 1Cr18/Cr18Ni9Ti | 铸铁 | 聚四氟乙烯 增强聚四氟乙烯 对位聚苯 | 聚四氟乙烯 对位聚苯 |

| 硝酸类 | Q61N-160/320P | 304/1Cr18Ni9Ti | 304/1Cr18Ni9Ti | |||

| 醋酸类 | Q61N-160/320R | 316/1Cr18Ni12Mo2Ti | 316/1Cr18Ni12Mo2Ti |

Q61N高压对焊球阀主要外形尺寸:

| 型号 | 公称通径 | 尺寸(mm) | |||||

| L | L1 | D | D1 | H | L0 | ||

| Q61N-320 | 10 | 150 | 60 | 90 | 17 | 58 | 220 |

| 15 | 170 | 70 | 100 | 23 | 62 | 220 | |

| 20 | 191 | 81 | 110 | 29 | 75 | 250 | |

| 25 | 205 | 95 | 115 | 36 | 80 | 250 | |

| 32 | 230 | 110 | 150 | 43 | 96 | 300 | |

| 40 | 260 | 120 | 170 | 49 | 111 | 400 | |

| 50 | 330 | 140 | 200 | 61 | 128 | 400 | |

| 65 | 360 | 150 | 225 | 80 | 180 | 500 | |

| 80 | 380 | 160 | 270 | 105 | 200 | 600 | |

| 100 | 430 | 188 | 320 | 118 | 245 | 800 | |

高压对焊球阀

高压对焊球阀是一种采用对焊连接方式的高压阀门,通过阀体与管道的焊接形成整体结构,适用于高压管路系统中控制介质的通断,具有连接牢固、密封、耐高压性能强的特点,是高压流体输送系统中的关键控制部件。

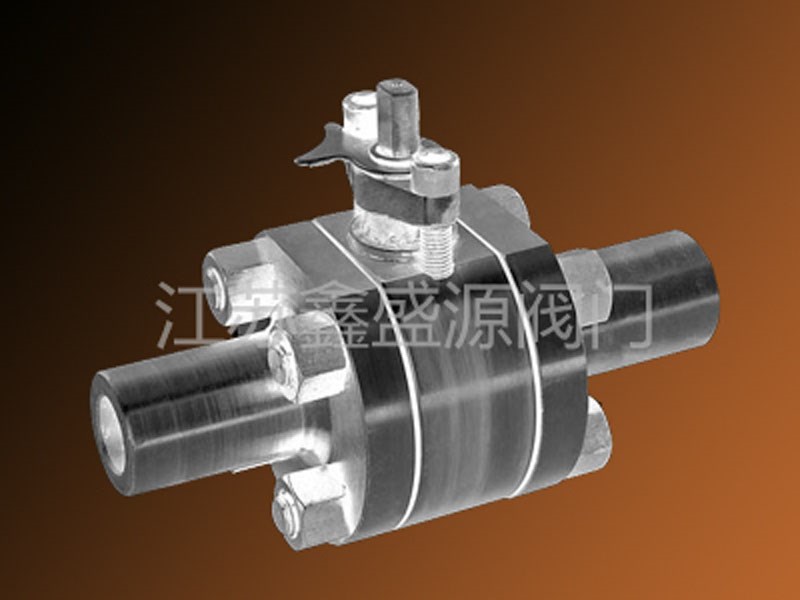

高压对焊球阀- 连接方式:采用对焊连接(如坡口焊接),阀体两端与管道直接焊接为一体,无额外泄漏点,连接强度高,能承受高压下的管道推力和振动,适用于中大口管径高压管道(通常DN25及以上),安装后稳定性很好。

高压对焊球阀- 结构特点:阀体多采用锻造或厚壁铸造工艺,材质选用高强度合金(如铬钼钢、不锈钢等),抗高压能力突出,工作压力可达PN16~PN420(或Class 150~Class 2500及以上);球体与阀座经精密加工,配合间隙小,确保高压下的启闭精准性。

高压对焊球阀- 密封性能:采用金属硬密封或金属与非金属复合密封结构,密封面经硬化处理(如堆焊硬质合金),耐磨损、抗冲刷,可实现高压工况下的长期密封,满足低泄漏或零泄漏要求。

高压对焊球阀- 安全设计:阀杆采用防吹出结构和双重密封(填料密封+倒密封),防止高压介质泄漏;部分型号配备防火结构,在密封件失效时仍能维持基本密封,适应易燃易爆介质场景。

高压对焊球阀- 适用范围:工作温度根据材质不同可达-40℃~550℃,适用于蒸汽、油品、天然气、高温高压水等介质,广泛应用于石油化工、煤化工、电力(尤其是超临界机组)、长输管线、高压锅炉系统等高压高温工业领域。

The high-pressure butt-weld ball valve is a type of high-pressure valve using butt-weld connection. It forms an integral structure through welding between the valve body the pipeline, is suitable for controlling the on-off of media in high-pressure pipeline systems. Featuring firm connection, reliable sealing, strong high-pressure resistance, it is a key control component in high-pressure fluid transmission systems.

The high-pressure butt-weld ball valve- Connection method: Adopts butt-weld connection (such as groove welding). Both ends of the valve body are directly welded with the pipeline into a whole, with no additional leakage points. The connection strength is high, capable of withstanding pipeline thrust vibration under high pressure. It is suitable for medium large diameter high-pressure pipelines (usually DN25 above), with excellent stability after installation.

The high-pressure butt-weld ball valve- Structural features: The valve body is mostly manufactured by forging thick-walled casting processes, with materials selected high-strength alloys (such as chrome-molybdenum steel, stainless steel, etc.), featuring outstanding high-pressure resistance. The working pressure can reach PN16~PN420 ( Class 150~Class 2500 above); the ball valve seat are precision-machined with small fitting clearance, ensuring accurate opening closing under high pressure.

The high-pressure butt-weld ball valve- Sealing performance: Adopts metal hard sealing metal-nonmetal composite sealing structure. The sealing surface is hardened (such as surfacing with hard alloy), resistant to wear erosion, can achieve long-term reliable sealing under high-pressure working conditions, meeting low leakage zero leakage requirements.

The high-pressure butt-weld ball valve- Safety design: The valve stem adopts a blow-out proof structure double sealing (packing seal + back seal) to prevent leakage of high-pressure media; some models are equipped with fire-safe structures, which can still maintain basic sealing when the seal fails, adapting to flammable explosive medium scenarios.

The high-pressure butt-weld ball valve- Application range: The working temperature can reach -40℃~550℃ depending on the material, suitable for media such as steam, oil products, natural gas, high-temperature high-pressure water, etc. It is widely used in high-pressure high-temperature industrial fields such as petrochemical, coal chemical, electric power (especially supercritical units), long-distance pipelines, high-pressure boiler systems.