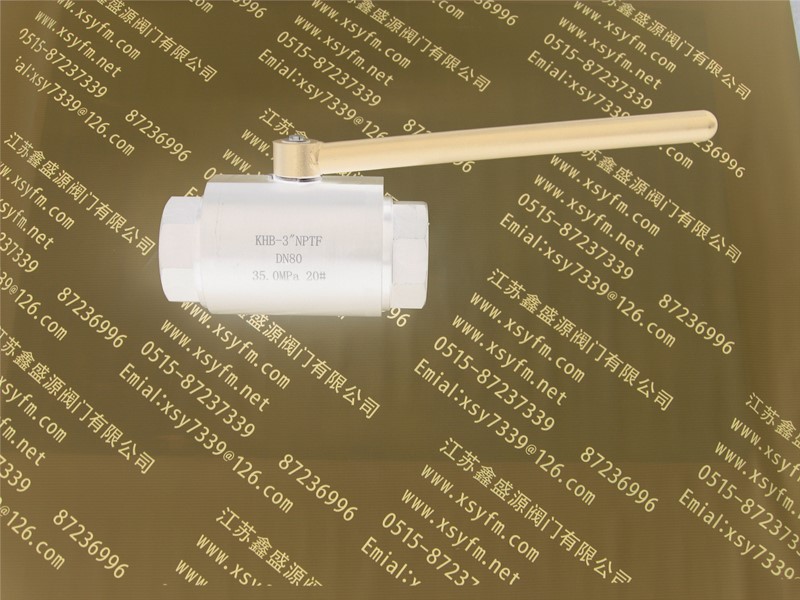

KHB内螺纹球阀

商品详情

性能特点

技术参数

KHB内螺纹球阀用于液压机械设备、液压开关、天然气等。高压内螺纹球阀问世于20世纪50年代,随着科学技术的飞速发展,生产工艺及产品结构的的不断改进,在短短的40年时间里,已迅速发展成为一种主要的阀类。在西方国家工业发达的国家,高压球阀的使用正在逐年不断的上升,在我国,球阀被广泛的应用在石油炼制、长输管线、化工、造纸、制药、水利、电力、市政、钢铁等行业,在国民经济中占有举足轻重的地位。

KHB内螺纹高压球阀主要用于截断或接通管路中的介质,亦可用于流体的调节与控制,其中硬密封 V 型球阀其 V 型球芯与堆焊硬质合金的金属阀座之间具有很强的剪切力,特别适用于含纤维、微小固体颗料等介质。而多通球阀在管道上不仅可灵活控制介质的合流、分流、及流向的切换,同时也可关闭任一通道而使另外两个通道相连。本类阀门在管道中一般应当水平安装。

Q11SA内螺纹超高压球阀它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。球阀适宜做开关、切断阀使用,但近来的发展已将球阀设计成使它具有节流和控制流量之用,如V型球阀。

KHB内螺纹球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻、耐高压。

3.紧密度好。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

KHB内螺纹球阀

KHB内螺纹球阀是一种采用内螺纹连接方式的小型球阀,广泛应用于低压至中高压流体系统中,以实现介质的快速通断控制。其核心设计特点是阀体两端加工有内螺纹(如NPT、G螺纹等),可直接与外螺纹管道或接头连接,安装便捷且结构紧凑,尤其适用于空间受限的管路系统。

KHB内螺纹球阀主要由球体、阀座、内螺纹阀体、阀杆及手柄等部件组成,工作原理基于球体的90°旋转:当手柄带动球体旋转至通道与管路轴线一致时,阀门全开,介质顺畅流通;旋转至通道与管路轴线垂直时,球体与阀座紧密贴合,实现密封,阻止介质泄漏。

KHB内螺纹球阀的优势包括:1. 连接方式简单,无需额外法兰或焊接,降低安装成本;2. 流通阻力小,球体通道设计为直通式,介质流过时压力损失小;3. 密封性能好,阀座多采用耐油、耐磨损的橡胶或聚四氟乙烯材料,适配水、油、气体等多种介质;4. 操作轻便,手柄转动灵活,可快速实现启闭,部分型号可配备锁定装置,防止误操作。

KHB内螺纹球阀其公称通径通常为DN6-DN50(或1/8″-2″),公称压力范围一般为16MPa-40MPa,工作温度根据材质不同可达-20℃-120℃,阀体材质多选用黄铜、碳钢或不锈钢,以适应不同工况的耐腐蚀需求。在应用上,KHB内螺纹球阀常见于液压系统、润滑系统、工程机械、机床及小型工业管路中。

English Translation

Product Overview of KHB Internal Thread Ball Valve

The KHB internal thread ball valve is a small-sized ball valve with internal thread connection, widely used in low to medium-high pressure fluid systems to realize rapid on-off control of media. Its core design feature is that both ends of the valve body are processed with internal threads (such as NPT, G threads, etc.), which can be directly connected to external thread pipelines joints. It is easy to install has a compact structure, especially suitable for pipeline systems with limited space.

The valve is mainly composed of components such as a ball, valve seat, internal thread valve body, valve stem, handle. Its working principle is based on the 90° rotation of the ball: when the handle drives the ball to rotate until the channel is aligned with the pipeline axis, the valve is fully open, the medium flows smoothly; when rotated until the channel is perpendicular to the pipeline axis, the ball fits tightly with the valve seat to achieve reliable sealing prevent medium lThe significant advantages of KHB internal thread ball valves include: 1. Simple connection mode, no additional flanges welding required, reducing installation costs; 2. Low flow resistance, the ball channel is designed as a straight-through type, resulting in small pressure loss when the medium flows through; 3. Reliable sealing performance, the valve seat is mostly made of oil-resistant wear-resistant rubber polytetrafluoroethylene materials, suitable for various media such as water, oil, gas; 4. Easy operation, the handle rotates flexibly, enabling quick opening closing, some models can be equipped with a locking device to prevent misoperation.

Its nominal diameter is usually DN6-DN50 ( 1/8″-2″), the nominal pressure range is generally 16MPa-40MPa, the working temperature can reach -20℃-120℃ depending on the material. The valve body material is mostly brass, carbon steel, stainless steel to meet the corrosion resistance requirements of different working conditions. In application, KHB internal thread ball valves are commonly used in hydraulic systems, lubrication systems, engineering machinery, machine tools, small industrial pipelines.