天然气防爆气动球阀

商品详情

性能特点

技术参数

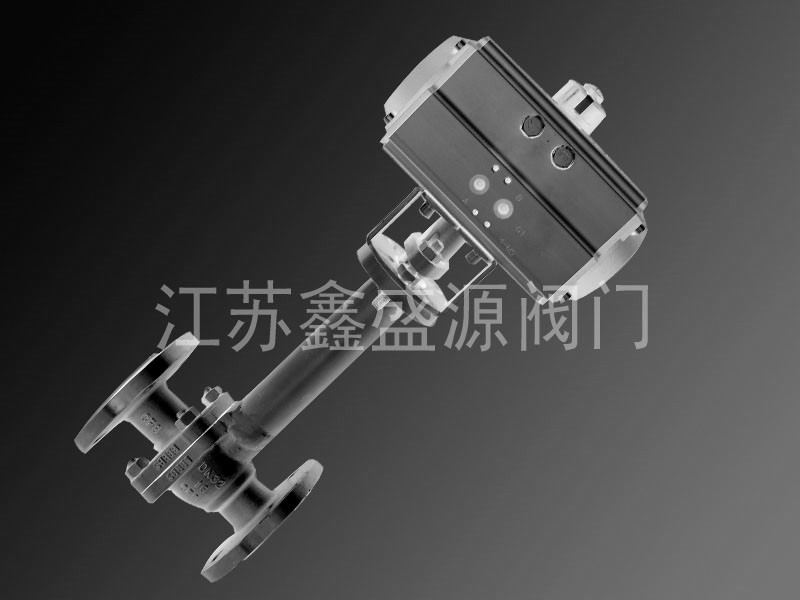

Q621N天然气防爆气动球阀也称防爆切断阀主要是针对加气站,使用介质为天然气而开发研究的特殊高压产品,该阀通过24V或者220V防爆电磁阀远程控制阀门工作。让整个站区的安全。主体采用高压冲击锻打,壳体强化处理,工作压力可在25.0MPa~60.0MPa长期正常使用,试验压力更可达到150.0MPa,密封件均采用全进口美国MTU材料,具有弹性高、手感轻、耐高压、耐腐蚀、抗氧化、密封稳定等优点。球和阀杆都用特殊的热处理工艺,使之刚柔兼之,经久耐磨。Q621N天然气防爆气动球阀目前在加气站的子母站上常用的连接方式有外螺纹焊接式、卡套式、内螺纹式和法兰式。而在这几个连接方式中又以外螺纹焊接式受用户青眯。外螺纹焊接式有别于三块式焊接球阀(Q61型焊接前要先松开4根对夹螺栓,把两端焊好后再装,这样不仅是容易泄漏,就是将来维修更换都不方便)具有安装简单、操作灵活、更换方便等优点。

天然气防爆气动球阀

天然气防爆气动球阀是一种专为天然气系统设计,具有防爆功能的阀门,通过气动装置控制,保障天然气输送和使用过程中的安全。

天然气防爆气动球阀- 结构特点:主要由阀体、球体、阀杆、密封圈和气动执行机构等组成。阀体通常采用不锈钢等耐腐蚀材料,内部有球形孔道。球体多为不锈钢材质,阀座密封圈常用聚四氟乙烯等材料。气动执行机构外壳一般由高强度铝合金或不锈钢制成,电气元件采用隔爆型设计。

天然气防爆气动球阀- 工作原理:利用气动执行机构提供动力,驱动球体旋转。当球体上的通孔与管道方向一致时,阀门开启,天然气可顺利通过;当球体旋转90°,使通孔与管道垂直时,阀门关闭,截断天然气流动。

天然气防爆气动球阀- 性能优势:具有好的防爆性能,符合相关防爆标准,能防止电气设备或操作过程中产生的火花引发爆炸。密封性能,可实现双向密封,有效防止天然气泄漏。操作便捷,可远程控制或自动化控制,通过压缩空气驱动,避免了电气火花的产生。流体阻力小,球体通道孔径与管道内径相当,较大的流量。

天然气防爆气动球阀- 适用范围:适用于天然气开采、输送和储存等环节,如井口装置、输气管道、加气站等。可在中高压环境下工作,压力范围一般为PN16-PN100,温度范围通常在-20℃至150℃,能适应多种工况。

The explosion - proof pneumatic ball valve for natural gas is a kind of valve specially designed for natural gas systems. It has explosion - proof function is controlled by a pneumatic device to ensure the safety of natural gas transportation use. The product overview is as follows:

The explosion - proof pneumatic ball valve- Structural features: It is mainly composed of valve body, ball, valve stem, sealing ring pneumatic actuator, etc. The valve body is usually made of corrosion - resistant materials such as stainless steel, with a spherical channel inside. The ball is mostly made of stainless steel, the valve seat sealing ring is commonly made of materials such as polytetrafluoroethylene. The shell of the pneumatic actuator is generally made of high - strength aluminum alloy stainless steel, the electrical components adopt an explosion - proof design.

The explosion - proof pneumatic ball valve- Working principle: It uses the pneumatic actuator to provide power to drive the ball to rotate. When the through - hole on the ball is in line with the pipeline direction, the valve is opened, natural gas can pass through smoothly. When the ball rotates 90 ° to make the through - hole perpendicular to the pipeline, the valve is closed, cutting off the flow of natural gas.

The explosion - proof pneumatic ball valve- Performance advantages: It has reliable explosion - proof performance, in line with relevant explosion - proof standards, can prevent sparks generated by electrical equipment during operation causing explosions. The sealing performance is excellent, it can achieve two - way sealing, effectively preventing the leakage of natural gas. It is convenient to operate, can be remotely controlled automatically controlled. Driven by compressed air, it avoids the generation of electrical sparks. The fluid resistance is small, the aperture of the ball channel is equivalent to the inner diameter of the pipeline, which can ensure a large flow rate.

The explosion - proof pneumatic ball valve- Scope of application: It is suitable for various links of natural gas extraction, transportation storage, such as wellhead devices, gas transmission pipelines, gas filling stations, etc. It can work in medium - high pressure environments, with a general pressure range of PN16 - PN100 a temperature range usually between - 20℃ 150℃, can adapt to a variety of working conditions.