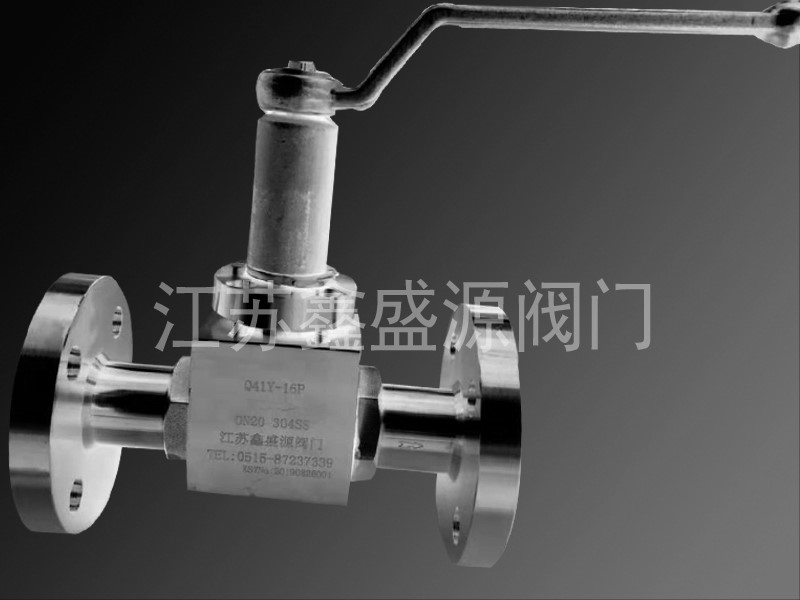

法兰硬密封球阀

商品详情

性能特点

技术参数

Q41Y法兰硬密封球阀的球和阀座都是通过喷焊STL合金后进行配合研磨。可以耐高温到650℃,高压42MPa,可以通过颗粒状介质。它具有旋转90度的动作,旋塞体为球体,有圆形通孔或通道通过其轴线。球阀在管路中主要用来做切断、分配和改变介质的流动方向,它只需要用旋转90度的操作和很小的转动力矩就能关闭严密。球阀适宜做开关、切断阀使用,但近来的发展已将球阀设计成使它具有节流和控制流量之用,如V型球阀。

Q41Y法兰硬密封球阀的主要特点是结构紧凑,密封稳定,结构简单,维修方便,密封面与球面常在闭合状态,不易被介质冲蚀,易于操作和维修,适用于水、溶剂、酸和天然气等一般工作介质,而且还适用于工作条件恶劣的介质,如氧气、过氧化氢、甲烷和乙烯等,在各行业得到广泛的应用。球阀阀体可以是整体的,也可以是组合式的。

Q41Y高温硬密封法兰球阀优点:

1.流体阻力小,全通径的球阀基本没有流阻。

2.结构简单、体积小、重量轻。耐高温 耐高压 方便安装执行机构。

3.紧密度好。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

4.操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

5.维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

6.在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

7.适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

8.由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

法兰硬密封球阀

法兰硬密封球阀是一种采用金属与金属硬密封结构、通过法兰连接的阀门,兼具高强度密封性能与结构稳定性,适用于高温、高压、含颗粒或腐蚀性介质的严苛工况,广泛应用于石油、化工、电力、冶金等行业的关键管道系统。

法兰硬密封球阀- 结构特点:阀体、球体、阀座等核心部件多采用锻造合金钢材(如WCB、304、316不锈钢等),经精密加工和研磨处理,确保金属密封面的平整度与配合精度;法兰接口符合相关标准(如GB、ANSI、DIN等),密封面形式包括突面(RF)、环连接面(RTJ)等,可与对应管道法兰稳固对接;硬密封副(球体与阀座均为金属材质)设计使阀门具备耐磨性、抗冲刷性,部分型号配备弹簧加载式阀座,可补偿密封面磨损,维持长期密封稳妥性。

法兰硬密封球阀- 工作原理:通过旋转阀杆带动球体旋转90°实现启闭。当球体通孔与管道通道中心线重合时,阀门全开,介质流通;旋转90°后,球体与阀座的金属密封面紧密贴合,利用金属的弹性变形实现高压密封,截断介质流动。操作可手动或搭配气动、电动执行器,满足自动化控制需求。

法兰硬密封球阀- 性能优势:硬密封结构耐温性强,工作温度范围可达-29℃至600℃,适用于高温蒸汽、热油等介质;耐压能力突出,公称压力通常为PN16-PN420(或Class 150-Class 2500),可适应高压差工况;抗腐蚀、抗磨损性能好,能输送含固体颗粒、粉尘或腐蚀性流体而不易损坏;法兰连接安装便捷,密封性稳定,维护周期长,适合长期连续运行的工业系统。

法兰硬密封球阀- 适用范围:适用于蒸汽、天然气、原油、酸碱溶液、含颗粒浆液等介质,公称通径一般为DN15-DN600。广泛应用于电厂锅炉系统、炼化装置、高压管道工程、冶金冶炼设备等,作为截断或调节设备使用。

Flanged hard-seal ball valve is a valve with metal-to-metal hard-seal structure flange connection, featuring high-strength sealing performance structural stability. It is suitable for harsh working conditions involving high temperature, high pressure, particle-containing corrosive media, is widely used in key pipeline systems in petroleum, chemical, electric power, metallurgy other industries.

Flanged hard-seal ball- Structural features: Core components such as valve body, ball, valve seat are mostly made of forged alloy steel (e.g., WCB, 304, 316 stainless steel, etc.), with precision machining grinding to ensure the flatness fitting accuracy of metal sealing surfaces. The flange interface complies with relevant standards (such as GB, ANSI, DIN, etc.), with sealing face types including Raised Face (RF), Ring Type Joint (RTJ), etc., which can be stably connected with corresponding pipeline flanges. The hard-seal pair (both ball valve seat are metal) design endows the valve with excellent wear resistance erosion resistance; some models are equipped with spring-loaded valve seats, which can compensate for sealing surface wear maintain long-term sealing reliability.

Flanged hard-seal ball- Working principle: The valve is opened closed by rotating the valve stem to drive the ball to rotate 90°. When the through-hole of the ball coincides with the center line of the pipeline channel, the valve is fully open, allowing efficient medium flow; after rotating 90°, the metal sealing surfaces of the ball valve seat fit tightly, achieving high-pressure sealing through elastic deformation of metal to cut off medium flow. It can be operated manually equipped with pneumatic/electric actuators to meet the needs of automatic control.

Flanged hard-seal ball- Performance advantages: The hard-seal structure has strong temperature resistance, with a working temperature range of -29℃ to 600℃, suitable for high-temperature steam, hot oil other media; it has outstanding pressure resistance, with a nominal pressure usually of PN16-PN420 ( Class 150-Class 2500), adaptable to high-pressure difference conditions; it has excellent corrosion resistance wear resistance, capable of conveying solid particle-containing, dust-laden corrosive fluids without easy damage; flange connection ensures convenient installation, stable sealing, a long maintenance cycle, suitable for industrial systems with long-term continuous operation.

Flanged hard-seal ball- Scope of application: Suitable for media such as steam, natural gas, crude oil, acid-alkali solutions, particle-containing slurry, with a nominal diameter generally of DN15-DN600. It is widely used in power plant boiler systems, refining chemical plants, high-pressure pipeline projects, metallurgical smelting equipment, etc., as a shut-off regulating device.