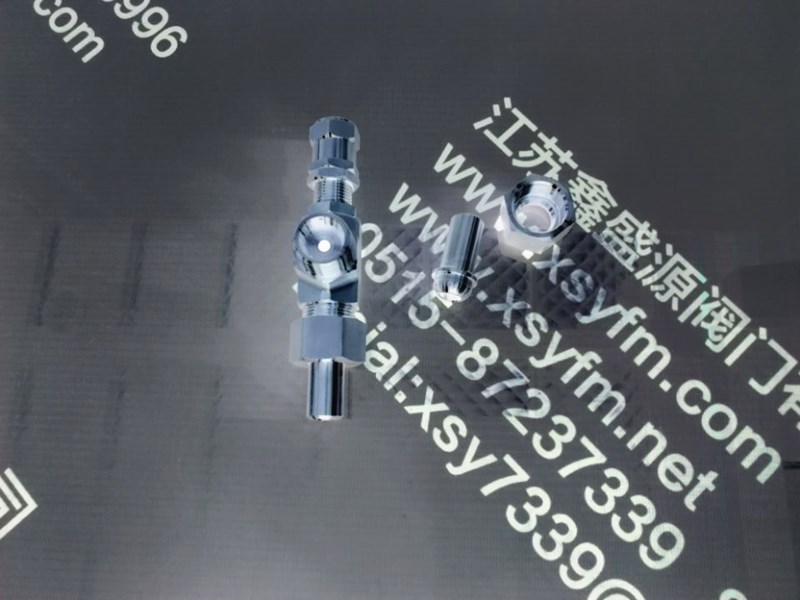

焊接式卸荷阀

商品详情

性能特点

技术参数

焊接式卸荷阀

焊接式卸荷阀是一种通过焊接方式直接集成于管路或系统的压力保护装置,用于在系统压力超过设定阈值时自动开启卸压,确保设备安全运行。其结构紧凑、密封性好,适用于高压、高温或对泄漏要求严格的工况,如石油化工、核电、船舶及重型机械等领域。

焊接式卸荷阀产品特点:

一体化焊接设计:阀体与管路采用焊接连接,避免法兰或螺纹接口的泄漏风险,适用于高压、振动环境。

高稳定性:硬密封结构或金属-to-金属密封,耐磨损且寿命长。

快速响应:直动式或先导式结构可选,卸压动作灵敏,确保系统瞬时超压保护。

焊接式卸荷阀定制化选项:可适配不同压力等级(如10MPa~100MPa)、介质(油/气/水)及焊接标准(GB、ANSI、DIN等)。

焊接式卸荷阀典型应用:

石油管道系统的超压保护

核电设备的高压回路安全控制

船舶液压系统的焊接集成阀组

注:可根据具体技术参数(如阀体材质、适用温度范围、认证标准等)补充细节。

Welded-Type Relief Valve Product Overview

A Welded-Type Relief Valve is a pressure protection device directly integrated into pipelines systems via welding. It automatically opens to release excess pressure when the system exceeds preset thresholds, ensuring operational safety. With a compact structure superior sealing performance, it is ideal for high-pressure, high-temperature, leak-critical applications such as petrochemical, nuclear power, marine, heavy machinery industries.

Welded-Type Relief Valve Product Overview Key Features:

Welded Integration: Eliminates leakage risks flanged/threaded connections, suitable for high-pressure high-vibration environments.

High Reliability: Hard-seal metal-to-metal sealing ensures wear resistance long service life.

Rapid Response: Optional direct-acting pilot-operated designs enable quick pressure relief for transient overload protection.

Customization: Adaptable to various pressure ratings (e.g., 10MPa–100MPa), media (oil/gas/water), welding standards (GB, ANSI, DIN).

Typical Applications:

Overpressure protection in oil pipelines

Safety control in high-pressure circuits of nuclear power equipment

Welded valve blocks for marine hydraulic systems