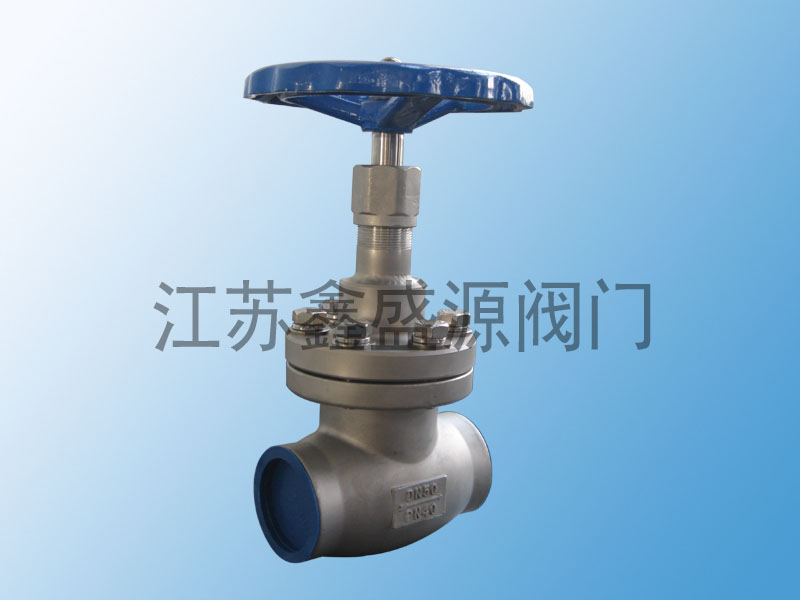

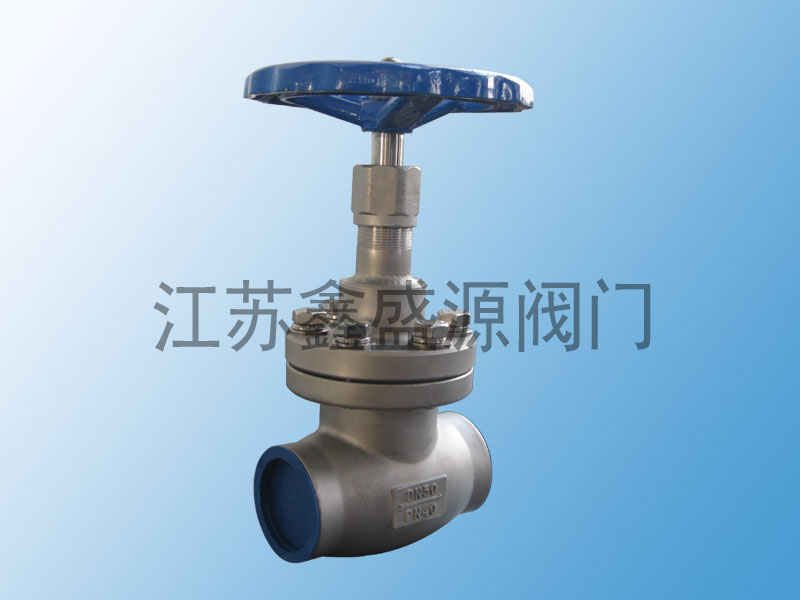

低温短轴截止阀

商品详情

性能特点

技术参数

DJ61F低温短轴截止阀主要用于低温液体贮运设备的管理系统,具有开关灵活、密封稳定的特点,也可用于其他低温和深冷介质的管理系统。低温短轴截止阀一般用于低温储罐的气向阀或接触低温液体面积较小的部位管路。

低温短轴截止阀

低温短轴截止阀是一种专门设计用于深冷介质(如液氮、液氧、液化天然气(LNG)、液态二氧化碳等)的专用阀门。其核心设计特点是采用了短轴结构,减少阀杆处于低温环境中的长度,从而有效防止因低温造成的操作困难、密封失效以及外部结冰等问题。

低温短轴截止阀主要特点:

短轴设计: 阀杆在关闭状态下大部分位于阀盖保温层或阀体外部,极大减少了冷量向填料函和操作部件的传递,确保阀门在超低温环境下仍能灵活启闭。

低温短轴截止阀延长阀盖: 通常配有延长颈阀盖,使填料函和阀杆密封部位远离低温流体,为填料函提供一个相对“温暖”的环境,防止密封件冻硬失效,并避免手轮操作部位结冰。

材料选择: 阀体、阀盖等主要部件采用适用于低温的材料,如不锈钢(304、316、316L),这些材料在低温下具有良好的抗冲击韧性和机械性能,防止脆性断裂。

低温短轴截止阀特殊密封: 采用低温环境下性能稳定的密封材料(如增强聚四氟乙烯、石墨等),确保阀门在低温工况下的密封稳定性。

安全设计: 通常设计有泄压孔(在阀瓣上方),防止因阀门中腔异常升压(如介质气化)而造成的危险,提高了使用安全性。

低温短轴截止阀应用领域:

广泛应用于空分、液化天然气(LNG)、石化、航空航天等行业的低温液体储存和输送系统,是控制低温介质安全截流的关键设备。

Cryogenic Short-Stem Globe Valve Product Overview

A Cryogenic Short-Stem Globe Valve is a specialized valve designed for handling cryogenic media, such as liquid nitrogen, liquid oxygen, liquefied natural gas (LNG), liquid carbon dioxide. Its core design feature is the short-stem structure, which aims to minimize the length of the valve stem exposed to the cryogenic environment. This effectively prevents operational difficulties, seal failure, external icing caused by extreme low temperatures.

Key Features:

Short-Stem Design: When closed, the majority of the stem is located within the bonnet insulation outside the valve body. This significantly reduces the transfer of cold to the stuffing box operating components, ensuring smooth opening closing even in ultra-cryogenic conditions.

Extended Bonnet: It is typically equipped with an extended neck bonnet. This positions the stuffing box stem sealing area away the cryogenic fluid, providing a relatively "warm" environment for the packing. This prevents the sealing elements freezing becoming ineffective avoids icing on the handwheel operation area.

Material Selection: Primary components like the valve body bonnet are manufactured materials suitable for low temperatures, such as stainless steel (304, 316, 316L). These materials maintain excellent impact toughness mechanical properties at cryogenic temperatures, preventing brittle fracture.

Specialized Sealing: Seals made materials with stable performance in cryogenic environments (e.g., reinforced PTFE, graphite) are used to ensure reliable sealing under low-temperature conditions.

Safety Design: Often features a pressure relief hole (above the disc) to prevent danger caused by abnormal pressure build-up in the valve cavity (e.g., media vaporization), enhancing operational safety.

Applications:

Widely used in cryogenic liquid storage transportation systems across industries such as air separation, liquefied natural gas (LNG), petrochemicals, aerospace. It is a critical device for the safe shut-off control of cryogenic media.