天然气低温高压止回阀

商品详情

性能特点

技术参数

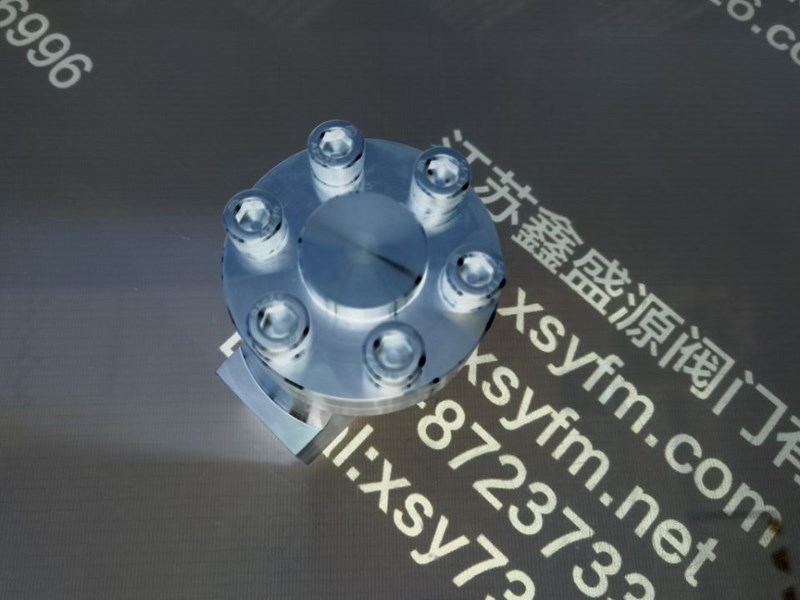

DH61Y低温高压止回阀的工作原理是在一个方向流动的流体压力作用下,阀瓣打开;流体反方向流动时,由流体压力和阀瓣的自重合阀瓣作用于阀座,从而切断流动。 DH61Y低温高压止回阀又称为逆流阀、逆止阀、背压阀、单向阀。这类阀门是靠管路中介质本身的流动产生的力而自动开启和关闭的,属于一种自动阀门。止回阀用于管路系统,其主要作用是防止介质倒流、防止泵及其驱动电机机反转,以及容器内介质的泄放。 DH61Y低温高压止回阀整体整体锻造而成,毛坯需经过低温处理后再精加工,该阀可以在-196℃的情况下耐压到42MPa,目前广泛应用在天然气行业。阀门通过承插焊和管道连接,具有安装方便 连接牢固 安全稳定等优点。

天然气低温高压止回阀

天然气低温高压止回阀是一种专为严苛的液化天然气(LNG) 工况设计的特殊阀门。它结合了超低温深冷处理、高压密封和防逆流三大核心功能,主要用于LNG输送系统、液化装置、接收站及再气化设施中,确保介质(-162°C及以下的LNG)在高压下单向流动,防止介质倒流,保护上游设备安全,是LNG产业链中的关键安全设备之一。

天然气低温高压止回阀主要特点:

超低温材料与设计: 阀体、阀瓣等主要承压件采用经深冷处理的奥氏体不锈钢(如304、316L),能使材料在-196°C的超低温下仍具有优良的抗冲击韧性和机械强度,防止脆性断裂。通常采用加长阀盖设计,将阀瓣导向机构与低温介质隔离,减少冷量传递,防止密封件冻硬和外部结冰。

天然气低温高压止回阀高压密封性: 采用金属对金属密封或特殊聚合物密封面,阀瓣与阀座经过精密研磨,确保在高压差工况下实现紧密关闭和零泄漏,满足高压管线的密封要求。

天然气低温高压止回阀低扭矩启闭与快速响应: 针对低温下介质粘度变化和高压背压,进行精准的弹簧载荷和结构优化设计,确保阀瓣在低流速下能灵活开启,在流量停止或逆流发生时能迅速关闭,减小水击压力(Water Hammer),关闭撞击轻,寿命长。

天然气低温高压止回阀全通径或缩径设计: 根据系统压力损失要求,可选择全通径设计以降低流阻,或采用缩径设计以满足更高压力等级和紧凑结构的需求。

天然气低温高压止回阀防火安全: 许多产品设计符合防火安全标准(如API 607/6FA),在火灾情况下仍能保持结构完整性和基本密封功能。

天然气低温高压止回阀应用领域:

主要应用于LNG液化工厂、LNG接收站、LNG槽车装载系统、LNG气化站、高压输气管线以及空分、化工等领域的低温高压流程中,作为关键管线的单向截止保护装置。

Natural Gas Cryogenic High-Pressure Check Valve Product Overview

A Natural Gas Cryogenic High-Pressure Check Valve is a specialty valve designed specifically for the demanding conditions of Liquefied Natural Gas (LNG) applications. It integrates three core functionalities: ultra-cryogenic service, high-pressure sealing, backflow prevention. Primarily used in LNG transportation systems, liquefaction plants, receiving terminals, regasification facilities, it ensures the unidirectional flow of medium (LNG at -162°C below) under high pressure, prevents reverse flow, protects upstream equipment. It is a critical safety component in the LNG industry chain.

Key Features:

Cryogenic Materials Design: Main pressure-containing parts like the body disc are made austenitic stainless steel (e.g., 304, 316L) that has undergone deep cryogenic treatment. This ensures the material maintains excellent impact toughness mechanical strength at ultra-low temperatures down to -196°C, preventing brittle fracture. Often features an extended bonnet design to isolate the disc guiding mechanism the cryogenic medium, reducing cold transfer preventing seal freezing external icing.

High-Pressure Sealing: Employs metal-to-metal seals special polymer seating surfaces. The disc seat are precision lapped to ensure tight shut-off zero leakage under high-pressure differential conditions, meeting the sealing requirements of high-pressure pipelines.

Low Torque Operation & Rapid Response: Optimized spring load structural design account for changes in media viscosity at low temperatures high backpressure. This ensures the disc opens smoothly even at low flow rates closes quickly upon flow cessation reversal, minimizing water hammer closing impact for enhanced service life.

Full-Bore Reduced-Bore Design: Depending on system pressure drop requirements, full-bore design can be selected for lower flow resistance, reduced-bore design can be used to meet higher pressure ratings compact space constraints.

Fire-Safe Design: Many products are designed to comply with fire-safe standards (e.g., API 607/6FA), maintaining structural integrity basic sealing functionality in the event of a fire.

Applications:

Widely used in LNG liquefaction plants, LNG receiving terminals, LNG tanker loading systems, LNG regasification stations, high-pressure transmission pipelines, as well as in cryogenic high-pressure processes in air separation chemical industries. It serves as a critical one-way shut-off protection device on key pipelines.