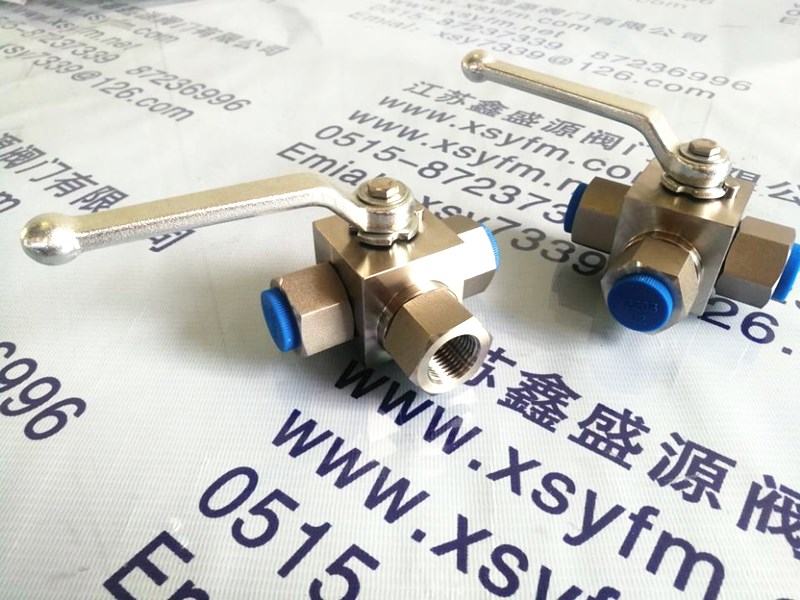

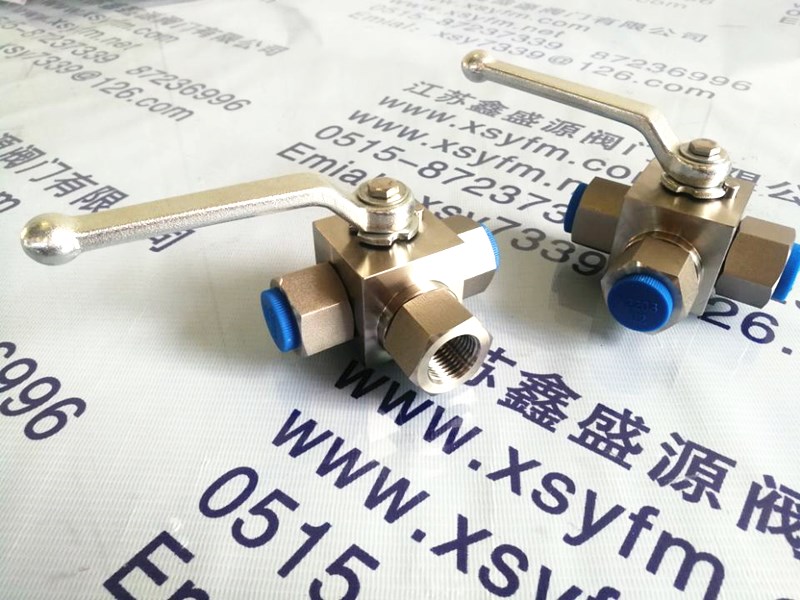

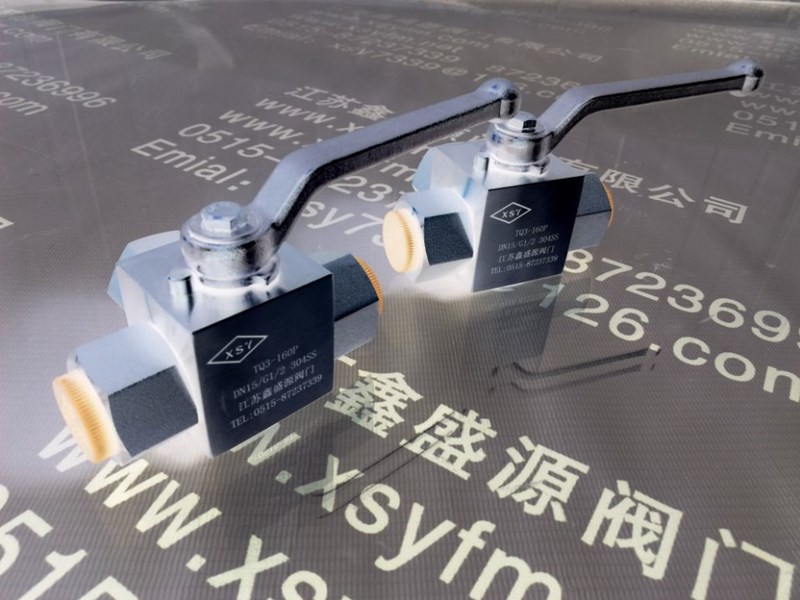

三通内螺纹换向球阀

商品详情

性能特点

技术参数

QT11 QL11三通内螺纹换向球阀在结构上分为T型和L型2种换向方式。这种阀的原理是以改变管线内的介质流向为目的,实现管道互通。由本厂自主研发生产的【球阀】质量、价格合理、售后服务完善。『内螺纹三通球阀』适用于各种轻重工业及楼宇管道。TQ3 LQ3三通内螺纹球阀广泛应用于:化工、石化、石油、造纸、采矿、电力、液化气、食品、制药、给排水、市政、机械设备配套、电子工业,城建等领域。

TQ3 LQ3三通内螺纹球阀特点:

(1)流体阻力小,全通径的球阀基本没有流阻。

(2)结构简单、体积小、重量轻。

(3)紧密稳定。它有两个密封面,而且目前球阀的密封面材料广泛使用各种塑料,密封性好,能实现完全密封。在真空系统中也已广泛使用。

(4)操作方便,开闭迅速,从全开到全关只要旋转90°,便于远距离的控制。

(5)维修方便,球阀结构简单,密封圈一般都是活动的,拆卸更换都比较方便。

(6)在全开或全闭时,球体和阀座的密封面与介质隔离,介质通过时,不会引起阀门密封面的侵蚀。

(7)适用范围广,通径从小到几毫米,大到几米,从高真空至高压力都可应用。

(8)由于球阀在启闭过程中有擦拭性,所以可用于带悬浮固体颗粒的介质中。

TQ3 LQ3三通内螺纹技术参数:

①公称压力:2.5MPa 4.0MPa 6.4MPa 10.0MPa 16.0MPa 32.0MPa 42.0MPa 50.0MPa 80.0MPa

②适用稳定范围:-20~232℃~350℃

③适用介质:水、油、气及某些腐蚀性液体(W.O.G)

三通内螺纹换向球阀产品介绍

三通内螺纹换向球阀是一种通过螺纹连接方式与管道系统相连,用于实现介质流向切换的阀门

三通内螺纹换向球阀通常分为“T”型和“L”型两种。

三通内螺纹换向球阀,阀门结构紧凑、外形美观,具有良好的密封性能。它以压缩空气或电力等为动力源,通过执行器带动球体旋转,实现对管道中介质流向的切换,也可使相互垂直的两个通道连通或关闭。三通内螺纹换向球阀:“L”型适用于介质流向切换,能让相互垂直的两个通道连通;

三通内螺纹换向球阀:“T”型则适用于介质的分流、合流或流向切换,可使三个通道相互连通或其中两个通道连通。阀门一般采用两阀座结构,也可根据用户需求采用四阀座结构。其任一通口可用作入口且无泄漏,维修方便,在系统卸压后,无需拆下整个阀体即可进行检查和维修。广泛应用于供水、石化、冶金、食品等管路系统中 。

Three - way internal thread reversing ball valves are usually divided into two types: "T" type "L" type. The valve has a compact structure a beautiful appearance, with good sealing performance. It uses compressed air, electricity, etc. as the power source, drives the ball to rotate through the actuator to achieve the switching of the medium flow direction in the pipeline, can also connect close the two mutually - perpendicular channels. The "L" type is suitable for the switching of the medium flow direction, which can connect the two mutually - perpendicular channels; the "T" type is suitable for the shunting, confluence flow - direction switching of the medium, which can connect the three channels to each other connect two of them. The valve generally adopts a two - seat structure, can also adopt a four - seat structure according to user requirements. Any port can be used as the inlet without leakage, it is convenient to maintain. After the system is depressurized, the inspection maintenance can be carried out without removing the whole valve body. It is widely used in pipeline systems such as water supply, petrochemical, metallurgy, food