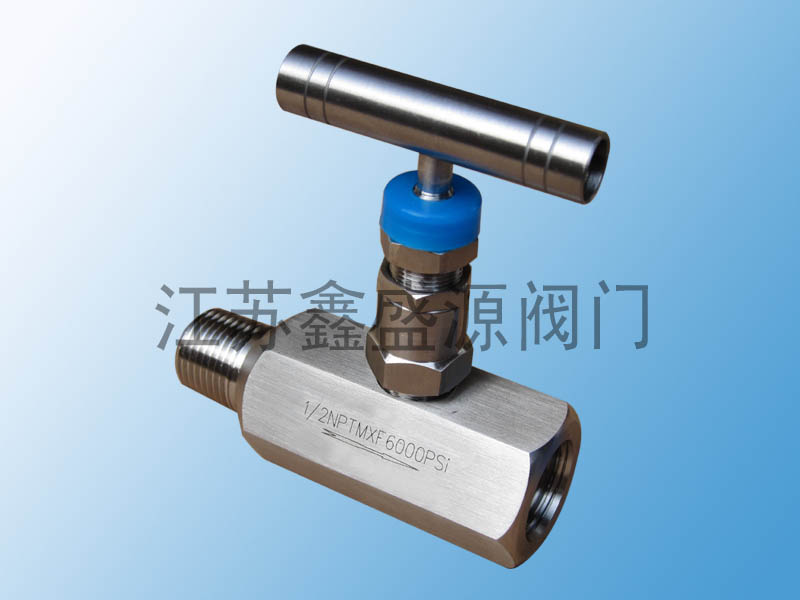

六方体美标针阀

商品详情

性能特点

技术参数

产品名称:六方体美标针阀

产品型号:1/2NPTM*F

工作压力:3000PSI~6000PSI(413bar),高可达10000PSI(689bar)

工作温度:

PTFE填料:-38oC 至 180oC (-100oF 至 356oF)

PPL 填料:-38oC 至 280oC (-100oF 至 536oF)

石墨填料:-24oC 至 480oC (-75oF 至 896oF)

连接端口:对焊 插焊

适用介质:水 油 气

六方体美标针阀优点:

1、两截阀杆设计,上阀杆螺纹淡化工艺处理

2、下阀杆表经经滚压硬化处理上阀杆螺纹的润滑脂与系统介质隔离

3、无旋转的下阀杆垂直运动代替旋转升降,减少阀杆行程对填料的磨擦,手感更轻便

4、阀门在全开位置具有背密封功能

5、可选面板安装

6、可安装手柄或者手轮操作,稳固耐用多种颜色手柄可供选择

7、每只阀门在出厂前均按设计压力的1.1倍进行氮气密封测试,并按额定工作压力的1.5倍水压进行壳体强度测试

六方体美标针阀

六方体美标针阀是一种采用六角形阀体设计的精密流量控制阀门,其工作原理基于针形阀芯与阀座的锥面密封配合,通过旋转调节实现流体控制。以下是其核心原理及技术特点的详细分析:

1. 基本工作原理

六方体美标针阀通过旋转手轮驱动阀杆,使针形阀芯(圆锥体)轴向移动,改变与阀座间的间隙大小,从而调节流量:

关闭状态:顺时针旋转手轮时,阀芯完全压入阀座锥面,形成金属硬密封(或复合密封),切断流体通路。密封面接触压力随介质压力升高而增强,实现“压力自紧”效果。

开启状态:逆时针旋转手轮,阀芯逐渐脱离阀座,形成环形流道。阀芯的细长锥形设计允许微米级开度调节,适用于小流量高精度控制(如0.1 mL/min)。

2. 六方体结构设计特点

六角形阀体:阀体外部为六角形(Hexagonal),便于使用扳手安装和拆卸,尤其适合空间受限的仪表管路或高压系统。

紧凑性与强度:六方体结构增强阀体抗压能力,配合锻造工艺(如A105或316L不锈钢),可承受≤10000Psi(约69MPa)高压。

密封组件:采用锥面密封(金属对金属或PTFE软密封),部分型号配备波纹管密封,彻底消除阀杆泄漏风险,适用于腐蚀性介质。

3. 核心性能参数

压力范围:1.6~42MPa(部分超高压型号达200MPa)。

温度范围:-29℃~+538℃(低温型号扩展至-196℃,高温型号达570℃)。

流量控制:公称通径DN6~DN25,适用于微小流量调节(如气相色谱仪或液压系统)。

材料兼容性:阀体与阀芯可选304/316不锈钢、铬钼钢或衬氟材料,耐腐蚀性满足NACE MR-01-75标准。

4. 典型应用场景

高压仪表管路:与压力表配套使用,防止压力冲击损坏传感器,如炼油厂催化裂化装置。

精密流体控制:实验室设备(如液相色谱仪)、航空航天燃油系统,需微调流量与压力的场合。

严苛工况:核电站主蒸汽管道(CLASS 800压力等级)、酸性油气田开采系统。

5. 与传统针阀的对比优势

特性六方体美标针阀普通针阀密封性能波纹管+锥面双重密封,泄漏等级A级单一填料密封,标准泄漏量安装便捷性六角阀体适配扳手,无需额外固定件需法兰或螺纹配合安装耐压能力10000Psi(超高压型号达200MPa)通常≤16MPa维护周期波纹管设计寿命10万次启闭需定期更换填料

总结

六方体美标针阀通过六角形阀体强化结构强度,结合针形阀芯的精密锥面密封,实现了高压、高精度流量控制。其设计特别适用于仪表测量、极端工况及空间受限的安装环境。选型时需根据介质特性(腐蚀性、粘度)和压力等级选择适配材质(如316L不锈钢)及密封形式(波纹管或金属硬密封)。

Working Principle of Hex-Body American Standard Needle Valve

The hex-body American standard needle valve is a precision flow control valve featuring a hexagonal valve body design. Its operation is based on the conical sealing interaction between a needle-shaped plug valve seat, achieving precise fluid regulation through rotational adjustment. Below is a detailed analysis of its core principles technical characteristics:

1. Basic Working Principle

The hex-body needle valve controls flow by rotating the handwheel to axially move the needle-shaped plug (tapered cone), thereby adjusting the gap between plug seat:

Closed Position: Clockwise rotation forces the plug into full contact with the seat's conical surface, creating a metal-to-metal ( composite) seal that blocks fluid flow. Sealing pressure increases with system pressure, achieving a "pressure-energized" sealing effect.

Open Position: Counterclockwise rotation gradually withdraws the plug, forming an annular flow path. The plug's fine taper enables micron-level adjustment (as precise as 0.1 mL/min) for low-flow applications.

2. Hexagonal Body Design Features

Hexagonal Exterior: The six-sided body (per ASME/ANSI standards) facilitates wrench installation/removal, particularly in confined spaces high-pressure instrument lines.

Compact Strength: Hexagonal geometry enhances structural integrity. Forged construction (A105 316L stainless steel) withstands ≤10,000 psi (≈69 MPa).

Sealing Systems: Conical sealing (metal-to-metal PTFE soft seats), with optional bellows seals to eliminate stem leakage in corrosive media.

3. Key Performance Specifications

Pressure Rating: 1.6–42 MPa (ultra-high-pressure models to 200 MPa).

Temperature Range: -29°C to +538°C (extended to -196°C for cryogenic versions; 570°C for high-temp models).

Flow Control: DN6–DN25 sizes for micro-flow regulation (e.g., HPLC systems hydraulic circuits).

Material Options: 304/316 stainless steel, Cr-Mo steel, PTFE-lined bodies meeting NACE MR-01-75 corrosion standards.

4. Typical Applications

High-Pressure Instrumentation: Protects gauges/sensors in refinery FCC units pressure surges.

Precision Fluid Systems: Laboratory equipment (e.g., GC/MS), aerospace fuel controls requiring fine flow/pressure tuning.

Extreme Service: Nuclear steam lines (CLASS 800), sour gas extraction systems.

5. Advantages vs. Conventional Needle Valves

FeatureHex-Body AS Needle ValveStandard Needle ValveSealingBellows + conical dual-seal (Leakage Class A)Single packing (standard leakage)InstallationHex wrenching, no additional fixturesRequires flanges/threaded fittingsPressureUp to 10,000 psi (200 MPa models)Typically ≤16 MPaMaintenanceBellows design: 100,000+ cyclesPeriodic packing replacement

Summary

The hex-body American standard needle valve combines structural strength its hexagonal form with precision conical sealing for high-pressure, high-accuracy flow control. Ideal for instrumentation, extreme conditions, space-constrained installations. Selection should consider media properties (corrosivity, viscosity), pressure class, material/sealing options (e.g., 316L bellows vs. metal-seated versions).