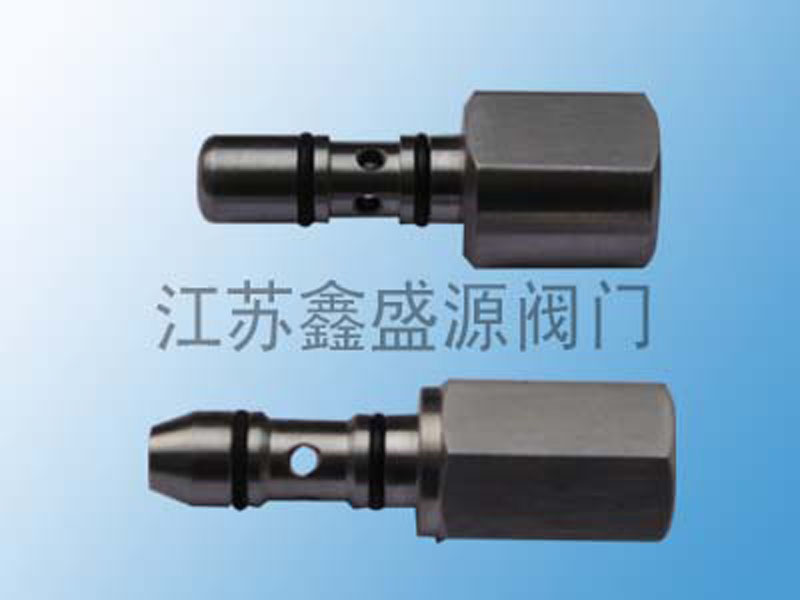

CNG加气机枪头

商品详情

性能特点

技术参数

型号:

AGA/CGA NGV1-94 CMV08

特点:

1. 寿命长:双向对准导向系统能使用寿命更长;

2. 连接寿命>10万次

3. 锁定系统:防止高压喷头连接到低压喷头或低压容器;

4. 自动化操作:单手自动操作,推入即可连接;

5. 锁紧球锁定稳定可靠性;

6. 独立套筒保护手与金属接触;

7. 止回阀装置能抢头未连接时断开;

参数:

1. 内径:7.5mm

2. 工作压力:200bar

3. 工作温度:-40度到85度

4. 流量:6500Nm3/h

CNG加气机枪头

· CNG加气机枪头基本定义:根据国家标准,CNG加气枪是“装于加气机上,与汽车用压缩天然气加气口连接,给车用气瓶充装天然气的手工操作专用装置”。它通常由加气嘴 (Nozzle)、三通阀 (Three-way valve) 和连接件组成。

· CNG加气机枪头核心功能:加气枪内部的三通阀是关键。加气结束后,它能排放加气嘴内残留的高压气体,确保拔枪操作在安全低压状态下进行。

· CNG加气机枪头安全设计与特性:为确保安全,加气枪设计有自动锁紧系统,能连接牢固;部分型号具备拉断保护功能,在意外拉扯时能自动断开,避免损坏设备;与天然气接触的非金属部件也需具备耐老化性和介质相容性。

· CNG加气机枪头主要技术参数:加气枪通常在高压下工作,例如常见最大工作压力为315 bar (约4568 PSI)或200-250 bar。流量性能是重要指标,不同型号的流量系数不同,以满足从轿车到巴士等不同车辆的加气速度需求。

· CNG加气机枪头兼容性与标准:加气枪必须与车辆加气口匹配。市场上许多产品遵循国际通用的 ANSI/CSA NGV1 和 ISO 14469 标准。在中国,还需符合 GB/T 19236—2003 国家标准。

CNG加气机枪头产品型号 主要特点 适用场景 标准/认证

史陶比尔 CMV 2-3型 自动锁紧,人体工学设计,避免加气口损坏 车队车辆快速或慢速加气 ANSI/CSA NGV1, ISO14469

史陶比尔 GMV 06型 自助式,聚碳酸酯材质,可选不同压力等级扳机 自助加气站 ANSI/CSA NGV1, ISO14469

史陶比尔 GMV 09/12型 大流量,内置卸压系统,铝和不锈钢材质 轻型、重型车辆快速加气 ANSI/CSA NGV1, ISO14469

OPW 5000系列 大流量,独特的内部密封和卡扣技术,可选直接排气 巴士、重型货车等大流量加气 ASME压力容器认证等

CNG加气机枪头选型与应用建议

在选择加气枪时,可以从以下几方面考虑:

· 车辆类型:根据主要服务的车辆(如私家车、公交车、重卡)选择匹配的加气枪型号和流量。

· CNG加气机枪头加气站模式:自助加气站可考虑GMV 06这类自助加气枪。

· 标准和法规:确保产品符合当地的质量与安全标准,例如中国的GB标准或国际ANSI/CSA标准。

希望以上信息能帮助你全面了解CNG加气机枪头。如果你对特定型号或技术细节有进一步疑问,欢迎继续提问。

以下是CNG加气机枪头的核心术语及产品概述的英文翻译:

· CNG加气枪:CNG Dispenser Nozzle / CNG Refueling Nozzle

· 枪头:Nozzle

· 加气机:Dispenser / Refueling Dispenser

· 压缩天然气:Compressed Natural Gas (CNG)

· 车辆加气口:Vehicle Receptacle / Vehicle Fill Receptacle

· 三通阀:Three-way Valve

· 拉断阀:Breakaway Coupling / Emergency Breakaway Device

· 工作压力:Working Pressure

· 流量:Flow Rate / Flow Capacity

CNG Dispenser Nozzle - Product Overview

A CNG Dispenser Nozzle is the output terminal of a CNG dispenser. Its core function is to safely rapidly connect to a vehicle's receptacle to complete the high-pressure refueling process.

· Definition: As defined by national standards, the CNG refueling nozzle is "a manually operated specialized device installed on the dispenser, which connects to the compressed natural gas refueling receptacle of a vehicle to fill the onboard CNG cylinder." It typically consists of a nozzle, a three-way valve, connectors.

· Core Function: The internal three-way valve is the key component. After refueling, it vents the residual high-pressure gas trapped within the nozzle, ensuring that disconnection can be performed safely under low pressure.

· Safety Design: To ensure operational safety, the nozzle incorporates an automatic locking mechanism to guarantee a secure connection. Many models are equipped with a breakaway function that automatically disconnects during accidental pull-away, preventing damage to the equipment. Non-metallic components in contact with the gas must also possess properties like aging resistance media compatibility.

· Technical Parameters: The nozzle operates under high pressure, with common maximum working pressures of 315 bar 200-250 bar. Flow performance is a critical metric, with different models offering varying flow coefficients to meet the refueling speed requirements of different vehicles, passenger cars to buses.

· Compatibility & Standards: The nozzle must be compatible with the vehicle's receptacle. Many products on the market adhere to internationally recognized standards such as ANSI/CSA NGV1 ISO 14469. In China, compliance with the GB/T 19236—2003 national standard is also required.