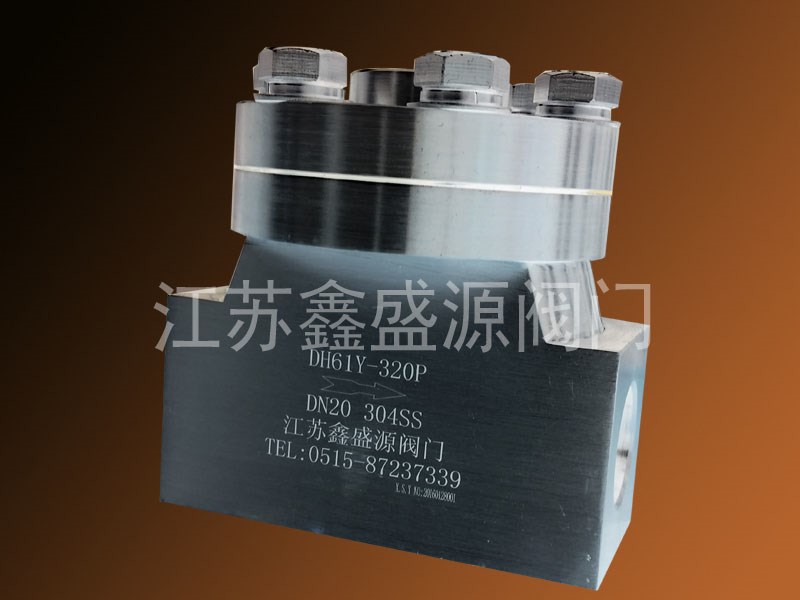

天然气高压止回阀

商品详情

性能特点

技术参数

H21X天然气高压止回阀的工作原理是启闭件靠介质流动和力量自行开启或关闭,以防止介质倒流的方向流动,以防止发生事故。在一个方向流动的流体压力作用下,阀瓣打开;流体反方向流动时,由流体压力和阀瓣的自重合阀瓣作用于阀座,从而切断流动。H21X天然气高压止回阀又称为逆流阀、逆止阀、背压阀、单向阀。这类阀门是靠管路中介质本身的流动产生的力而自动开启和关闭的,属于一种自动阀门。止回阀用于管路系统,其主要作用是防止介质倒流、防止泵及其驱动电机机反转,以及容器内介质的泄放。H21X天然气高压止回阀整体外形都是六角形式,是参考德国的设计风格而成,H21X天然气高压止回阀是通过外螺纹活接焊接和管道连接,具有安装方便 连接牢固 方便更换等优点。目前天然气行业广泛应用。

天然气高压止回阀

天然气高压止回阀是一种专为高压天然气输送和应用系统设计的关键安全装置。其主要功能是防止介质(天然气)在高压工况下倒流,从而保护上游设备(如压缩机、泵、储罐和管道系统)免受逆流引发的损害,确保整个管道系统的安全、稳定运行。

天然气高压止回阀核心特点:

天然气高压止回阀高压设计:采用高强度材料(如碳钢、不锈钢)和特殊结构设计,能够承受天然气管道系统中的高压(通常从Class 600到2500甚至更高)。

天然气高压止回阀稳定密封:通过金属密封或高性能软密封材料(如PTFE、石墨),确保在高压差下实现零泄漏或微泄漏,满足严格的密封要求。

天然气高压止回阀快速响应:阀瓣设计确保对流量变化反应灵敏,在流量停止或逆流开始的瞬间迅速关闭,有效消除水锤现象。

低流阻:流线型阀体设计使流体通道顺畅,压力损失小,有助于降低系统运行能耗。

天然气高压止回阀专为天然气介质:材料选择和处理均考虑天然气的特性,如防腐蚀、抗硫化氢(H₂S)等。

天然气高压止回阀多种结构形式:主要包括旋启式、升降式和轴流式,以适应不同的安装空间、压力等级和流量要求。

天然气高压止回阀典型应用:

天然气长输管线主干线及支线

天然气压缩站出口/入口

城市燃气门站和调压站

储气库(地下储气库UGS)的注采系统

液化天然气(LNG)接收站及再气化设施

工业用户及发电厂的天然气供应系统

Product Overview of High-Pressure Natural Gas Check Valves

A high-pressure natural gas check valve is a critical safety device specifically designed for high-pressure natural gas transmission application systems. Its primary function is to prevent the backflow of the medium (natural gas) under high-pressure conditions, thereby protecting upstream equipment (such as compressors, pumps, storage tanks, pipeline systems) damage caused by reverse flow ensuring the safe stable operation of the entire pipeline system.

Key Features:

High-Pressure Design: Constructed with high-strength materials (e.g., carbon steel, stainless steel) special structural designs to withstand the high pressures (typically Class 600 to 2500 beyond) common in natural gas pipeline systems.

Reliable Sealing: Utilizes metal seals high-performance soft sealing materials (e.g., PTFE, graphite) to ensure zero minimal leakage under high pressure differentials, meeting stringent sealing requirements.

Rapid Response: The disc is designed to be highly responsive to flow changes, enabling quick closing the instant flow stops reverse flow begins, effectively mitigating water hammer effects.

Low Flow Resistance: A streamlined valve body design ensures a smooth fluid passage with minimal pressure drop, helping to reduce system energy consumption.

Designed for Natural Gas Service: Material selection treatment consider the properties of natural gas, such as corrosion resistance resistance to hydrogen sulfide (H₂S).

Various Design Types: Mainly include swing, piston (lift), axial flow types to accommodate different installation spaces, pressure ratings, flow requirements.

Typical Applications:

Mainlines branch lines of long-distance natural gas transmission pipelines

Outlet/Inlet of natural gas compressor stations

City gate stations pressure regulation stations

Injection production systems for Underground Gas Storage (UGS) facilities

LNG receiving terminals regasification plants

Natural gas supply systems for industrial users power generation plants