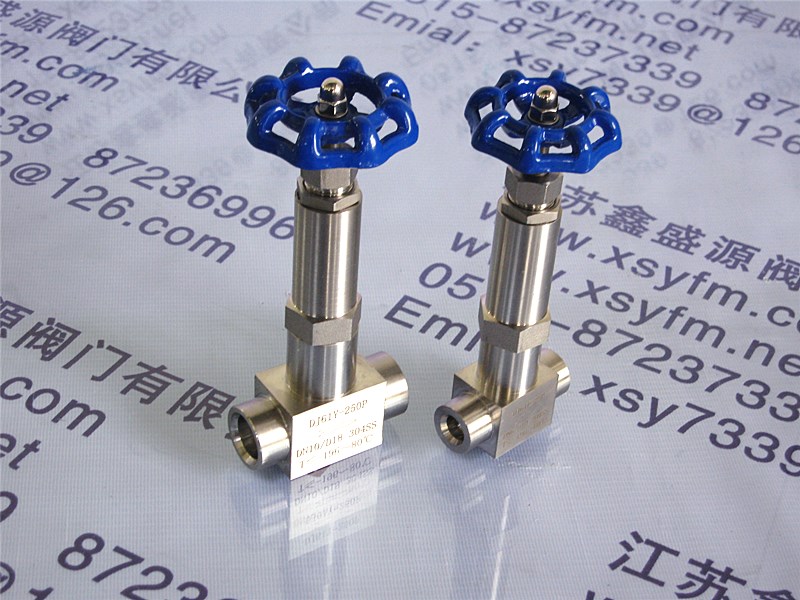

低温高压针型阀

商品详情

性能特点

技术参数

DJ21Y低温高压针型阀的启闭件是塞形的阀瓣,密封面呈平面或锥面,阀瓣沿流体的中心线作直线运动。阀杆的运动形式,有升降杆式(阀杆升降,手轮不升降),也有升降旋转杆式(手轮与阀杆一起旋转升降,螺母设在阀体上)。低温高压截止阀只适用于全开和全关,不允许作调节和节流。低温高压针型阀应用于气体液化设备、空分设备;天然气液化、储运设备;液态氧、氮、氩、氢、二氧化碳低温贮槽及槽车;变压吸附制氧、氮设备。DJ21Y低温高压针型阀广泛应用于能源、石化、冶金、航天、核工业、铁道等行业等行业。

DJ21Y低温高压针型阀结构特点:

1、结构简单,制造和维修比较方便;

2、工作行程小,启闭时间短;

3、密封性好,密封面间磨擦力小,寿命较大;

4、流体阻力大,开启和关闭时所需力较大;

5、不适用于带颗粒、粘度较大、易结焦的介质;

6、调节性能较差。

DJ21Y低温高压针型阀性能参数:

| 公称通径 | DN10mm~50mm |

| 公称压力 | PN32.0MPa |

| 适用介质 | 液氧、液氮、液氩、液化天然气、液态二氧化碳、液态丙烷等 |

| 适用温度 | -196℃~+150℃ |

DJ21Y低温高压针型阀主要零件材料:

| 阀体、阀盖 | 0Cr18Ni9 |

| 阀瓣、阀杆 | 0Cr18Ni9 |

| 密封圈 | T2 |

| 填料 | PTFE |

DJ21Y低温高压针型阀主要尺寸:

| 产品型号 | DJ61Y-320P低温高压截止阀 | 重量(kg) | |||||||

| 产品代号 | 通径DN(mm) | 尺 寸(mm) | |||||||

| H开 | H关 | D1 | D2 | L | A | D0 | |||

| DJ61Y10 | 10 | 258 | 250 | 10 | 14.5 | 10 | 80 | 160 | 7.0 |

| DJ61Y15 | 15 | 258 | 250 | 15 | 22.5 | 10 | 110 | 160 | 7.2 |

| DJ61Y20 | 20 | 322 | 310 | 20 | 28.5 | 10 | 120 | 250 | 11.1 |

| DJ61Y25 | 25 | 322 | 310 | 25 | 34.5 | 15 | 120 | 250 | 11.4 |

| DJ61Y40 | 40 | 390 | 370 | 40 | 49.5 | 15 | 180 | 400 | 22.8 |

| DJ61Y50 | 50 | 390 | 370 | 50 | 61.5 | 15 | 200 | 450 | 23.3 |

低温高压针型阀

低温高压针型阀是专门用于控制低温高压介质流动的特殊阀门,采用细长的锥形阀针(Needle)和阀座配合实现微流量调节关断。主要应用于LNG、液氮、液氧等低温介质的高压输送系统,要求阀门在-196℃的极低温度和高压(通常Class 600以上)工况下仍能实现调节和气泡级密封。

低温高压针型阀核心特点:

精密流量调节

细长锥形阀针实现毫米级行程控制

多螺纹细牙杆设计,调节精度高

开启圈数通常≥10圈,实现精细调节

低温高压针型阀高压密封稳定

金属硬密封+软密封复合结构

锥面密封比压高,适用压差≥42MPa

阀杆密封采用柔性石墨+PTFE组合

低温高压针型阀低温适应性

主体材料:深冷处理316L/304不锈钢

延长颈设计:防止填料函结冰

低温专用填料:柔性石墨+Inconel 718弹簧

低温高压针型阀安全结构特点

防吹出阀杆结构(Anti-blowout stem)

手轮限位锁定装置

防火防静电设计

低温高压针型阀典型应用:

LNG高压泵出口调节

低温实验装置流量控制

空分设备液氧/液氮精密调节

低温介质取样系统

航天推进剂加注系统

Product Overview of Cryogenic High-Pressure Needle Valves

Cryogenic High-Pressure Needle Valves are specialized valves designed for precise control of cryogenic high-pressure media flow. They utilize a slender tapered needle seat configuration to achieve micro-flow regulation reliable shut-off. Primarily used in high-pressure transmission systems for cryogenic media such as LNG, liquid nitrogen, liquid oxygen, these valves maintain precise regulation bubble-tight sealing under extreme conditions of -196℃ high pressure (typically Class 600 above).

Key Features:

Precise Flow Regulation

Slender tapered needle for millimeter-scale stroke control

Multi-thread fine screw design for high adjustment accuracy

Typically ≥10 turns to open for fine adjustment

High-Pressure Sealing

Metal hard seal + soft seal composite structure

High specific pressure on conical surface, suitable for ΔP≥42MPa

Stem sealing using flexible graphite + PTFE combination

Cryogenic Adaptation

Body material: Deep-cryo treated 316L/304 stainless steel

Extended bonnet: Prevents packing freezing

Cryogenic packing: Flexible graphite + Inconel 718 spring

Safety Features

Anti-blowout stem design

Handwheel limit locking device

Fire-safe anti-static design

Typical Applications:

LNG high-pressure pump outlet regulation

Flow control in cryogenic experimental devices

Precision regulation in air separation units (liquid oxygen/nitrogen)

Cryogenic media sampling systems

Aerospace propellant loading systems

Technical Specifications:

Pressure Rating: Class 800-2500

Temperature Range: -196℃ to +80℃

Leakage Class: ANSI B16.104 Class VI

Connection Types: SW, BW, NPT

Materials: SS316L, Monel, Inconel