美标焊接止回阀

商品详情

性能特点

技术参数

美标焊接止回阀有三种阀盖设计形式。一是螺栓式阀盖,按这种设计形式设计的阀门,其阀体与阀盖用螺栓螺母连接,缠绕式垫片(316夹柔性石墨制造)密封。客户有特殊要求时也可采用金属环连接。二是设计形式是焊接式阀盖,按这种设计形式的阀门,其阀体与阀盖用螺纹连接,全焊密封。客户有特殊要求时也可采用透焊连接。第三种是压力自紧式阀盖,按这种设计形式设计的阀门,其阀体与阀盖用螺纹连接,内压自密环密封。

设计结构和特征:

美标锻钢止回阀的设计与制造符合MSSP-118和ASME B16.34.检验与测试按API 598,标记按MSS-SP-25。

结构:

全径或缩径

![]() 升降式止回阀

升降式止回阀 ![]() 球式止回阀

球式止回阀 ![]() 旋启式止回阀

旋启式止回阀

![]() 按需求内置弹簧

按需求内置弹簧

![]() 螺栓连接、缠绕垫片密封式阀盖,螺纹连接、全焊密封式阀盖以及螺纹连接内压自紧式阀盖

螺栓连接、缠绕垫片密封式阀盖,螺纹连接、全焊密封式阀盖以及螺纹连接内压自紧式阀盖

![]() 整体式上密封座

整体式上密封座

![]() 承插端符合ASME B16.11

承插端符合ASME B16.11

![]() 螺纹连接端(NPT)符合ANSI/ASME B1.20.1

螺纹连接端(NPT)符合ANSI/ASME B1.20.1

![]() 阀瓣可变换为节流型、针型、球型

阀瓣可变换为节流型、针型、球型

相关压力:

·800LB

·900LB~1500LB

·800LB、900LB~1500LB

·900LB~2500LB

| NPS | 缩径 | 3/8” | 1/2” | 3/4” | 1” | 11/4” | 11/2” | 2” | |

| 全径 | 3/8” | 1/2” | 3/4” | 1” | 11/4” | 11/2” | 2” | ||

| L | 79 | 79 | 92 | 111 | 120 | 152 | 172 | 200 | |

| W | 61 | 61 | 65 | 79 | 95 | 103 | 118 | 132 | |

| 重量 | 螺栓式 | 1.4 | 1.2 | 1.5 | 3.1 | 3.9 | 5.6 | 8.9 | 12.5 |

| 焊接式 | 1.1 | 1.0 | 1.2 | 2.9 | 3.3 | 4.9 | 8.1 | 10.9 | |

800LB、900LB~1500LB

标准材质明细表:

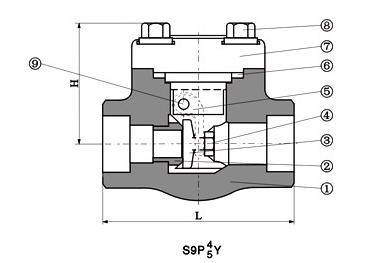

| 序号 | 零件名称 | CStoASTM | AStoASTM | SStoASTM | |

| A105 | F22 | F304(L) | F316(L) | ||

| 1 | 阀体 | A105 | A182F22 | A182F304(L) | A182F316(L) |

| 2 | 阀座 | A276410 | A276304 | A276F304(L) | A276F316(L) |

| 3 | 阀瓣 | A276420 | A276304 | A276F304(L) | A27F316(L) |

| 4 | 螺母 | A1942H | A1944 | A1948 | A1948M |

| 5 | 摇杆 | A105 | A182F22 | A182F304(L) | A182F316(L) |

| 6 | 垫片 | 316夹柔性石墨 | 316夹PTFE | ||

| 7 | 阀盖 | A105 | A182F22 | A182F304(L) | A182 F316(L) |

| 8 | 螺栓 | A193B7 | A193B16 | A193B8(M) | A193B8(M) |

| 9 | 销钉 | a276420 | A182F304 | A182F316 | |

| 适用介质 | 水、蒸汽、油品等 | 水、蒸汽、油品等 | 硝酸、醋酸等 | ||

| 适用温度 | -29℃~425℃ | -29℃~550℃ | -29℃~200℃ | ||

尺寸(MM)和重量(KG):

| NPS | 3/8” | 1/2” | 3/4” | 1” | 11/4” | 11/2” | 2” | |

| L | 800LB | 79 | 79 | 92 | 111 | 120 | 120 | 140 |

| 900LB~1500LB | 92 | 111 | 111 | 120 | 120 | 140 | 178 | |

| W | 800LB | 61 | 61 | 78 | 84 | 101 | 120 | 133 |

| 900LB~1500LB | 79 | 79 | 79 | 97 | 105 | 120 | 140 | |

| 重量 | 800LB | 1.1 | 1.0 | 1.9 | 3.9 | 4.5 | 7.3 | 10.0 |

| 900LB~1500LB | 3.1 | 3.0 | 3.6 | 4.3 | 6.1 | 8.8 | 12.6 | |

美标焊接止回阀

美标焊接止回阀是一种采用对焊(Butt Welding)或承插焊(Socket Welding) 连接的阀门,其设计与制造主要遵循 ASME/ANSI B16.34 等美国标准。它能自动阻止管道介质倒流,核心特点是焊接连接,密封稳定,适用于高温、高压等苛刻工况。

· 美标焊接止回阀设计与制造标准:通常遵循 ASME/ANSI B16.34, API 6D 等。

· 美标焊接止回阀结构长度标准:通常遵循 ASME B16.10。

· 焊接坡口标准:通常遵循 ANSI B16.25。

· 试验与检验标准:通常遵循 API 598, API 6D 等。

美标焊接止回阀主要特点

1. 密封稳定:阀门中腔常采用压力自紧式密封,介质压力越高,密封性能越好。阀瓣和阀座密封面常采用司太立(Stellite)钴基硬质合金堆焊,耐磨、耐高温、耐腐蚀、抗擦伤。

2. 结构紧凑坚固:焊接连接使阀门与管道成为整体,减少了泄漏点,结构紧凑。内装式的销轴结构,减小外泄漏点。

3. 高性能:阀门耐压部件选用优良耐热合金钢制造,高温性能好,承受压力高,耐用。

4. 维护简便:部分型号采用螺栓式阀盖,便于维护。

美标焊接止回阀主要零件材料

美标焊接止回阀的零件材料根据压力等级和适用介质有所不同,常见材料组合如下:

美标焊接止回阀零件名称 常见材料牌号

阀体 Body A216 WCB, A217 WC6, WC9

阀瓣 Disc WCB, WC6, WC9 等,密封面堆焊硬质合金

阀座 Seat 25, 15CrMoA, 12Cr1MoVA 等,密封面堆焊硬质合金

摇杆 Arm WCB, WC6, WC9

阀盖 Bonnet 25, 15CrMoA, 12Cr1MoVA

销轴 Pin Shaft 1Cr17Ni2, 20Cr1MoVA

密封环 Sealing Ring 软钢或增强柔性石墨 S soft steel reinforced flexible graphite

美标焊接止回阀主要外形连接尺寸

以下是一些常见的美标焊接止回阀(如 H64Y 型)的参考尺寸(单位:mm):

公称通径 压力等级 L H 重量 (kg)

2-1/2" 1500Lb 254 282 57

3" 1500Lb 325 300 57

4" 1500Lb 406 350 80

6" 1500Lb 559 400 180

8" 1500Lb 711 490 270

10" 1500Lb 864 540 430

12" 1500Lb 991 650 630

公称通径 压力等级 L H 重量 (kg)

2-1/2" 2000Lb 330 240 40

3" 2000Lb 368 305 60

4" 2000Lb 457 315 95

6" 2000Lb 610 465 186

8" 2000Lb 762 528 415

10" 2000Lb 914 613 658

12" 2000Lb 1041 680 1200

请注意:不同制造商和型号的阀门尺寸可能有所不同,建议您查阅具体产品的官方样本以获取准确数据。

Product Overview: American Standard Welding Check Valve

The American Standard Welding Check Valve is a type of valve that utilizes butt welding socket welding connections. Its design manufacturing primarily adhere to American standards such as ASME/ANSI B16.34. It automatically prevents the backflow of medium in pipelines. Its core characteristics include welded connections, reliable sealing, suitability for demanding conditions like high temperature high pressure.

· Design & Manufacturing Standards: Typically conform to ASME/ANSI B16.34, API 6D, etc.

· Face-to-Face Dimensions: Typically conform to ASME B16.10.

· Test & Inspection Standards: Typically conform to API 598, API 6D, etc.

Key Features

1. Reliable Sealing: The valve middle chamber often employs a pressure self-tightening seal – the higher the medium pressure, the better the sealing performance. The disc seat sealing surfaces are often hardfaced with Stellite cobalt-based hard alloy, making them wear-resistant, high-temperature resistant, corrosion-resistant, anti-galling.

2. Compact Robust Structure: Welded connection integrates the valve with the pipeline, reducing potential leak points resulting in a compact structure. The built-in pin shaft structure minimizes external leakage points.

3. High Performance: Pressure-resistant parts are made selected quality heat-resistant alloy steel, offering good high-temperature performance, high pressure-bearing capacity, durability.

4. Easy Maintenance: Some models feature a bolted bonnet design for easier maintenance.

Main Part Materials

The materials for main parts vary according to pressure rating suitable media. Common material combinations are as follows:

Part Name Common Material Designations

Body A216 WCB, A217 WC6, WC9

Disc WCB, WC6, WC9, etc., with hardfaced sealing surface

Seat 25, 15CrMoA, 12Cr1MoVA, etc., with hardfaced sealing surface

Arm WCB, WC6, WC9

Bonnet 25, 15CrMoA, 12Cr1MoVA

Pin Shaft 1Cr17Ni2, 20Cr1MoVA

Sealing Ring S soft steel (reinforced flexible graphite)

Main Face-to-Face & Connection Dimensions

The following are reference dimensions (Unit: mm) for some common American Standard Welding Check Valves (e.g., Type H64Y):

NPS Pressure Rating L H Weight (kg)

2-1/2" 1500Lb 254 282 57

3" 1500Lb 325 300 57

4" 1500Lb 406 350 80

6" 1500Lb 559 400 180

8" 1500Lb 711 490 270

10" 1500Lb 864 540 430

12" 1500Lb 991 650 630

NPS Pressure Rating L H Weight (kg)

2-1/2" 2000Lb 330 240 40

3" 2000Lb 368 305 60

4" 2000Lb 457 315 95

6" 2000Lb 610 465 186

8" 2000Lb 762 528 415

10" 2000Lb 914 613 658

12" 2000Lb 1041 680 1200

Please note: Dimensions may vary by manufacturer model. Refer to the official product catalog for precise data specific to the product.