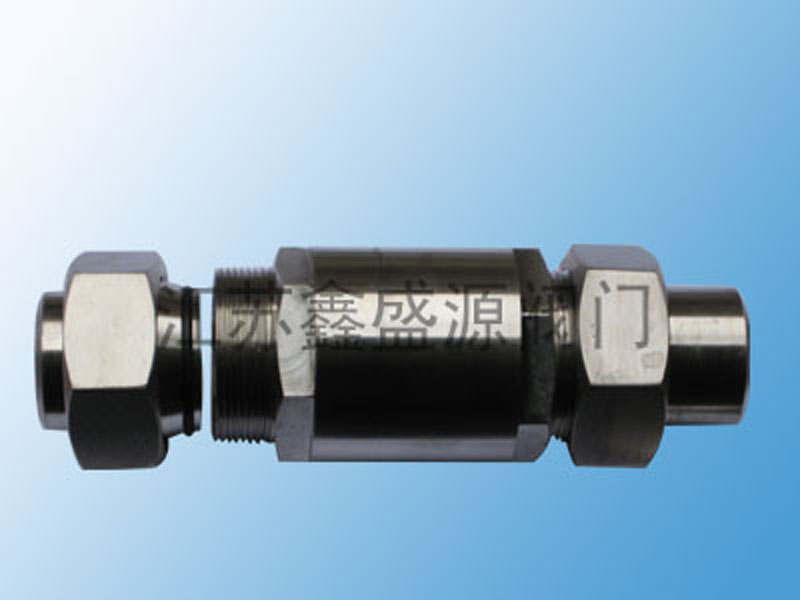

锥密封焊接止回阀

商品详情

性能特点

技术参数

焊接式止回阀又称为逆流阀、逆止阀、背压阀、单向阀。这类阀门是靠管路中介质本身的流动产生的力而自动开启和关闭的,属于一种自动阀门。止回阀用于管路系统,其主要作用是防止介质倒流、防止泵及其驱动电机机反转,以及容器内介质的泄放。焊接式单向阀只允许介质向一个方向流动,而且阻止方向流动。

公称压力:PN2.5 PN4 PN6.4 PN16 PN40Mpa

公称通径:DN5~DN125

适用介质:油﹑水﹑气等多种非腐蚀性或腐蚀性介质

适用温度:-20℃~+440℃ -70℃~-240℃ ≤540℃ ≤570℃等

制造材料:20#﹑1Cr18Ni9Ti﹑304﹑316﹑316L﹑12Cr1Mov等

锥密封焊接止回阀是一种采用金属锥面密封(Metal-to-Metal Cone Seal) 技术,并通过焊接方式与管道连接的止回阀。它代表了高压、高温及苛刻工况下流体控制解决方案,其核心功能是实现流体的严格单向流动,并凭借出色的密封性彻底阻止任何形式的介质反向泄漏。

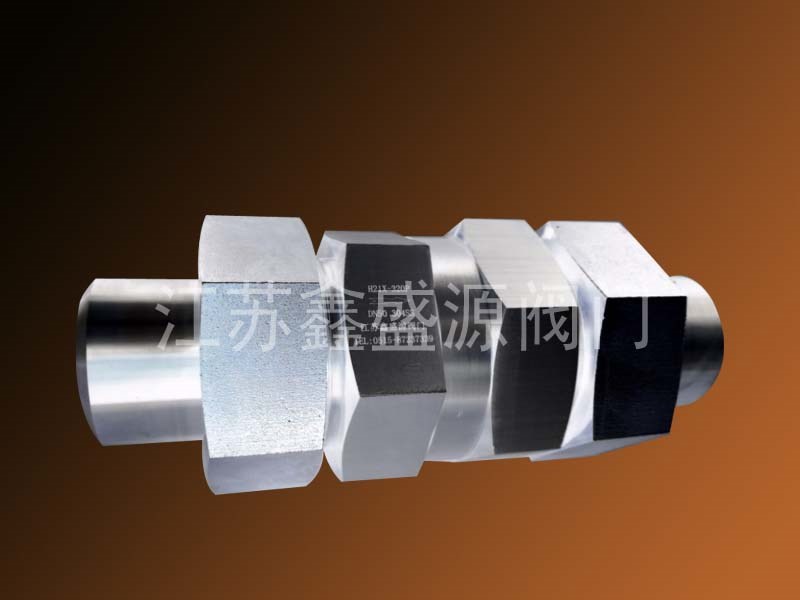

锥密封焊接止回阀的核心特征在于其锥形阀瓣与阀座的配合设计。在弹簧预紧力和系统压力的共同作用下,锥形密封副产生极高的表面比压,形成的线密封或面密封。阀体端部通常为对焊(BW)或承插焊(SW)接口,通过焊接与管道形成长久性的一体化连接,从根本上消除了连接处的泄漏风险。其设计与材料严格遵循ASME、ASTM等标准,确保其在极端条件下的稳定性。

锥密封焊接止回阀主要特点:

密封性能: 金属锥面硬密封结构,密封比压高,可实现零泄漏(Zero Leakage),适用于蒸汽、高温油品、易燃易爆及有毒介质。

耐高温高压: 全金属结构及焊接连接,无非金属密封件老化问题,适用于Class 1500~4500甚至更高的压力等级及550°C以上的高温工况。

锥密封焊接止回阀抗冲刷与耐磨损: 密封面常采用硬质合金(如司太立Stellite)堆焊,极大提高了在含有颗粒物、高速流体等苛刻工况下的使用寿命。

锥密封焊接止回阀快速关闭与低水锤: 优化的弹簧加载设计确保阀门响应迅速,关闭速度快,能有效减弱系统压力波动和水锤冲击。

结构紧凑与高稳定性: 焊接式连接结构紧凑,整体重量轻,且无法兰连接潜在的泄漏点,稳定性极高。

锥密封焊接止回阀典型应用:

高温高压蒸汽系统: 电站主蒸汽管道、过热蒸汽系统。

石油化工关键装置: 加氢裂化、催化重整装置的高压反应产物管道。

油气开采与输送: 井口装置、高压集输管线、注汽锅炉出口。

合成氨与尿素装置: 高压工艺气体管道。

任何对密封有极端要求的苛刻工况。

Product Overview of Cone-Seal Welded Check Valves

Product Overview:

A Cone-Seal Welded Check Valve is a type of check valve that utilizes metal-to-metal cone seal technology connects to the piping via welding. It represents a premium solution for fluid control in high-pressure, high-temperature, severe service conditions. Its core function is to ensure strict unidirectional flow completely prevent any form of media backflow leakage, thanks to its exceptional sealing performance.

The valve's defining feature is the mating design of its conical disc seat. Under the combined action of spring preload system pressure, the conical sealing pair generates extremely high surface pressure, creating an excellent line face seal. The valve ends are typically butt weld (BW) socket weld (SW) connections, which form a permanent, integral joint with the pipeline through welding, eliminating the risk of leakage at the connection point. Its design materials strictly comply with standards such as ASME ASTM, ensuring reliability under extreme conditions.

Key Features:

Premium Sealing Performance: The hard metal cone-seal structure provides high sealing specific pressure, achieving zero leakage. It is suitable for steam, high-temperature oils, flammable, explosive, toxic media.

High-Temperature & High-Pressure Resistance: The all-metal construction welded connection eliminate the issue of non-metallic seal aging. It is suitable for pressure classes 1500 to 4500 beyond, temperatures exceeding 550°C.

Erosion & Abrasion Resistance: The sealing surfaces are often hard-faced with alloys like Stellite, significantly extending service life in severe services containing particulates high-velocity flow.

Rapid Closing & Low Water Hammer: The optimized spring-assisted design ensures quick response fast closing speed, effectively dampening system pressure fluctuations water hammer shock.

Compact Structure & High Reliability: The welded design is compact lightweight, with no potential leak points flanged connections, offering extremely high reliability.

Typical Applications:

High-Temperature & High-Pressure Steam Systems: Main steam lines superheated steam systems in power plants.

Critical Petrochemical Units: High-pressure reactor effluent lines in hydrocracking catalytic reforming units.

Oil & Gas Production & Transmission: Wellhead equipment, high-pressure gathering pipelines, outlet of steam injection boilers.

Ammonia & Urea Plants: High-pressure process gas lines.

Any severe service with extreme sealing requirements.

关键术语翻译 (Key Terminology Translation):

锥密封焊接止回阀: Cone-Seal Welded Check Valve / Metal Cone-Seal Welded Check Valve

金属锥面密封: Metal-to-Metal Cone Seal

锥形阀瓣: Conical Disc / Cone-shaped Disc

阀座: Seat

硬质合金堆焊: Hardfacing / Stellite Overlay

司太立: Stellite

弹簧加载: Spring-Assisted / Spring-Loaded

零泄漏: Zero Leakage

对焊: Butt Weld (BW)

承插焊: Socket Weld (SW)

苛刻工况: Severe Service