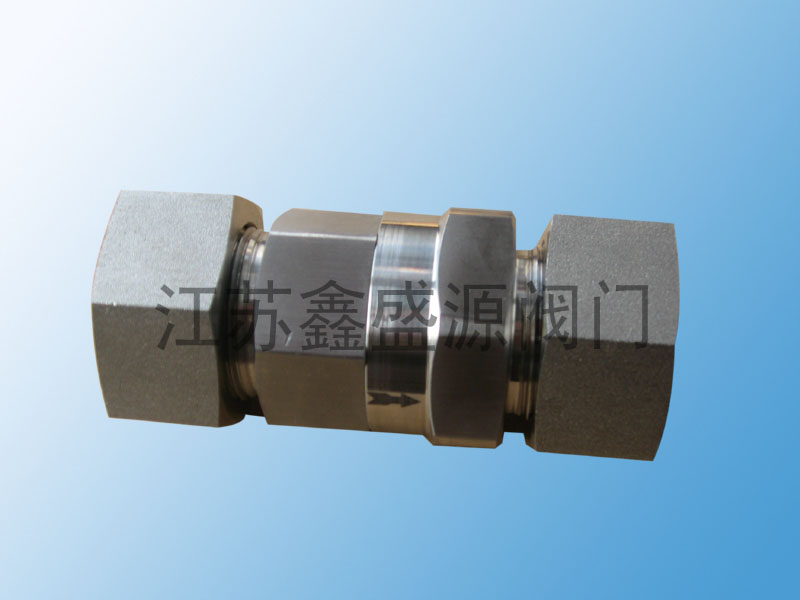

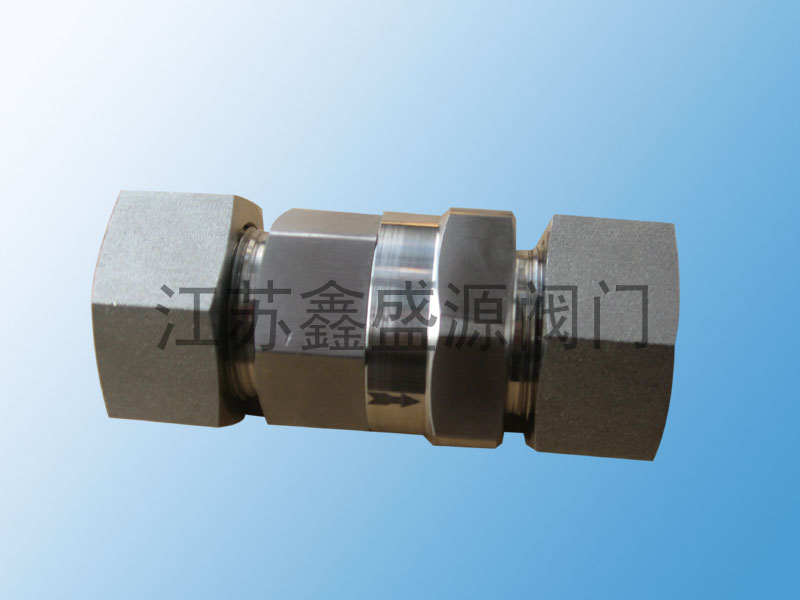

压缩机高压单向阀

商品详情

性能特点

技术参数

压缩机高压单向阀

压缩机高压单向阀,也常被称为压缩机高压止回阀或逆止阀,是一种用于压缩机系统的自动阀门。它的核心功能是防止介质(如空气、油、制冷剂等)在压缩机停机或工况变化时发生逆向流动。这能有效避免高压气体回流至压缩机,防止压缩机反转、系统压力异常下降以及由此引发的设备损坏或效率损失。它广泛应用于空压机、制冷、消防、石油化工和天然气等各种高压管路系统中。

压缩机高压单向阀工作原理:当压缩机工作,介质正向流动时,流体压力会克服弹簧力、阀瓣重力或摩擦力,推动阀瓣(或阀芯)开启,允许介质通过。当压缩机停止或介质停止流动/发生逆流时,阀瓣会在弹簧作用力、自身重力以及逆流介质的力量下自动迅速关闭,形成密封,从而阻止介质倒流。

✨ 压缩机高压单向阀主要特点

· 高压密封与耐冲击:阀门采用金属硬密封(如堆焊硬质合金)或高性能弹性密封圈(如进口PEEK)。阀瓣和阀座的密封面通常采用不同硬度的硬质合金喷焊而成,密封稳定,耐磨、耐高温、抗擦伤性能好,寿命长。部分产品采用主密封圈预紧、高裙边护卫、高背压限位等结构,以满足高压密封与冲击要求。

· 压缩机高压单向阀结构紧凑与高性能:采用直筒型活塞构造、内装摇臂旋启式或升降式等结构,体积小,重量轻。部分阀门阀芯设有三爪导向与大截面引流结构,降低了介质阻力损失。

· 安装维护考量:根据设计,有直通式、直角式等多种形式,连接方式可采用螺纹、法兰、对焊、卡套等。部分型号满足水平与下垂安装及振动场合的应用要求。结构简单,动作可信,维修方便。

压缩机高压单向阀主要技术参数

为了让您更清晰地了解压缩机高压单向阀的性能指标,我整理了以下关键参数表格:

压缩机高压单向阀参数类别 具体内容/范围

公称压力 (Nominal Pressure) PN1.0-32.0MPa 或更高(如达42.0MPa),部分产品工作压力可达 2,000~15,000 PSI (约13.8~103.4 MPa),甚至有产品声称达120MPa

公称通径 (Nominal Diameter) DN3~DN200, NPS 1/4 ~NPT2 等

适用温度 (Applicable Temperature) -196℃ ~ +540℃ (视阀体材质和密封材料而定)

阀体材质 (Body Material) 不锈钢 (如 304, 316, 316L, CF8, CF8M等 );碳钢 (如 WCB);合金钢 (如 WC6, WC9);哈氏合金等

连接形式 (Connection Form) 螺纹、法兰、对焊、承插焊、卡套式等

适用介质 (Suitable Media) 压缩空气、氮气、液化气、天然气、油品、水蒸气、制冷剂(兼容CFC、HFC和HCFC)等多种气体或液体

重要提示:以上信息整合自多个公开渠道,不同制造商的产品在规格和性能上可能存在差异。在实际选型和安装前,强烈建议您向供应商索要并仔细阅读具体产品的官方说明书和技术图纸,以确保其完全符合您的应用需求。

压缩机高压单向阀选型、安装与维护要点

· 选型注意事项:

· 根据压缩机的工作压力、介质特性和温度选择合适的阀门压力等级、材质和密封形式。

· 注意安装空间和流向要求,确认阀门的连接方式与管路匹配。

· 安装注意事项:

· 安装时,务必使介质正常流动方向与阀体上指示的箭头方向相一致。

· 对于液压或气动系统,直通式单向阀通常用螺纹连接安装在管路上,直角式则有螺纹、板式、法兰等多种连接形式。

· 焊接连接时,需注意控制阀体温度,防止内部密封件(如尼龙阀芯、弹性密封圈)因高温变形损坏。

· 常见故障与维护:

· 常见故障主要包括阀瓣打碎和介质倒流。

· 阀瓣打碎通常是由于阀瓣前后介质压力处于接近平衡而互相“拉锯”的状态,阀瓣频繁与阀座拍打所致,脆性材料(如铸铁、黄铜)阀瓣易损坏。预防的办法是采用阀瓣为韧性材料的止回阀。

· 介质倒流多因密封面破坏或夹入杂质引起。修复密封面和清洗杂质,通常能防止倒流。

· 如果高压单向阀损坏,高压气体可能倒流冲击压缩机或其他部件(如阀片),造成进一步损坏,发现后需立即停止运行并更换损坏零件。

Product Overview: Compressor High-Pressure Check Valve

The compressor high-pressure check valve, often referred to as a compressor high-pressure non-return valve reverse valve, is an automatic valve used in compressor systems . Its core function is to prevent the medium (such as air, oil, refrigerant, etc.) flowing in reverse when the compressor stops operating conditions change . This effectively prevents high-pressure gas flowing back into the compressor, avoiding compressor reversal, abnormal system pressure drop, subsequent equipment damage efficiency loss . It is widely used in various high-pressure pipeline systems such as air compressors, refrigeration, fire protection, petrochemical, natural gas .

Operating Principle: When the compressor operates the medium flows forward, the fluid pressure overcomes the spring force, disc gravity, friction force, pushing the disc ( spool) open allowing the medium to pass through . When the compressor stops the medium stops flowing/reverses, the disc closes automatically rapidly under the action of the spring force, its own weight, the pressure of the reverse medium, forming a seal preventing backflow .

Key Features

· High-Pressure Sealing & Impact Resistance: The valve employs metal hard seals (e.g., hardfaced with hard alloy) high-performance elastic sealing rings (e.g., imported PEEK) . The sealing surfaces of the disc seat are often hardfaced with hard alloys of different hardness levels, ensuring reliable sealing, good wear resistance, high-temperature resistance, excellent anti-galling properties, a long service life . Some products use structures like pre-tightened main seal rings, high skirt edge protection, high backpressure limit stops to meet high-pressure sealing impact requirements .

· Compact Structure & High Performance: It adopts structures such as straight barrel piston construction, built-in swing arm, lift type, resulting in small volume light weight . The spool of some valves features three-claw guidance large cross-section flow guiding structures, reducing medium flow resistance loss .

· Installation & Maintenance Considerations: Depending on the design, there are various forms like straight-through right-angle, with connection methods including thread, flange, butt weld, ferrule . Some models meet the application requirements for horizontal vertical installation vibration conditions . They feature simple structure, reliable operation, convenient maintenance.

Main Technical Parameters

Parameter Category Specific Content/Range

Nominal Pressure PN1.0-32.0MPa higher (e.g., up to 42.0MPa), some products have working pressures up to 2,000~15,000 PSI (approx. 13.8~103.4 MPa), with the highest claims even reaching 120MPa

Nominal Diameter DN3~DN200, NPS 1/4 ~NPT2, etc.

Applicable Temperature -196℃ ~ +540℃ (depending on body material sealing material)

Body Material Stainless Steel (e.g., 304, 316, 316L, CF8, CF8M, etc.); Carbon Steel (e.g., WCB); Alloy Steel (e.g., WC6, WC9); Hastelloy, etc.

Connection Form Thread, Flange, Butt Weld, Socket Weld, Ferrule type, etc.

Suitable Media Compressed air, nitrogen, liquefied gas, natural gas, oil, steam, refrigerant (compatible with CFC, HFC, HCFC), various other gases liquids

Important Note: The above information is integrated multiple public sources. Product specifications performance may vary by manufacturer. It is strongly recommended that you consult the supplier for carefully review the official instructions technical drawings of the specific product before actual selection installation to ensure it fully meets your application requirements.

Selection, Installation & Maintenance Points

· Selection Considerations:

· the appropriate valve pressure rating, material, sealing form based on the compressor's working pressure, media characteristics, temperature .

· Pay attention to installation space flow direction requirements, confirming the valve's connection method matches the pipeline .

· Installation Considerations:

· During installation, ensure the normal flow direction of the medium is consistent with the arrow direction indicated on the valve body .

· In hydraulic pneumatic systems, straight-through check valves are typically installed with threaded connections, while right-angle types have various connections like thread, plate, flange .

· For welded connections, control the valve body temperature to prevent damage to internal seals (e.g., nylon spool, elastic seals) high temperatures .

· Common Failures & Maintenance:

· Common failures mainly include disc breakage media backflow .

· Disc breakage is often caused by the medium pressure on both sides of the disc being nearly balanced creating a "seesaw" state, leading to frequent pounding of the disc against the seat. Discs made of brittle materials (like cast iron, brass) are prone to damage. The preventive method is to use a check valve with a disc made of tough material .

· Media backflow is often caused by damaged sealing surfaces entrapped impurities. Repairing the sealing surface cleaning impurities can usually prevent backflow .

· If the high-pressure check valve is damaged, high-pressure gas may flow back impact the compressor other components (e.g., valve plates), causing further damage. Operation should be stopped immediately damaged parts replaced upon discovery .