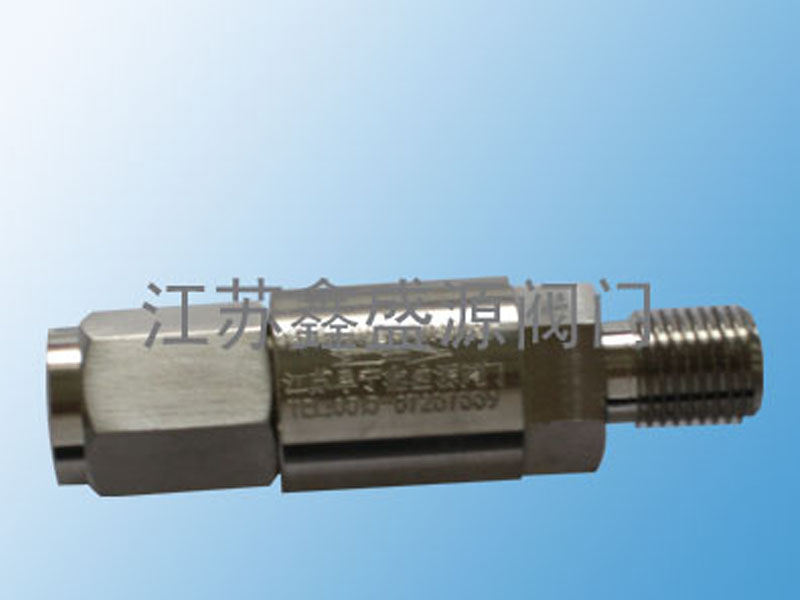

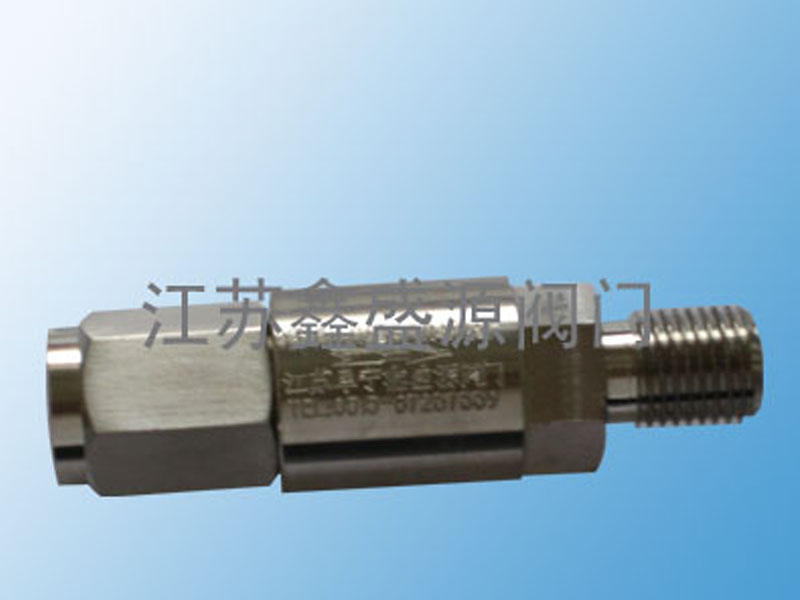

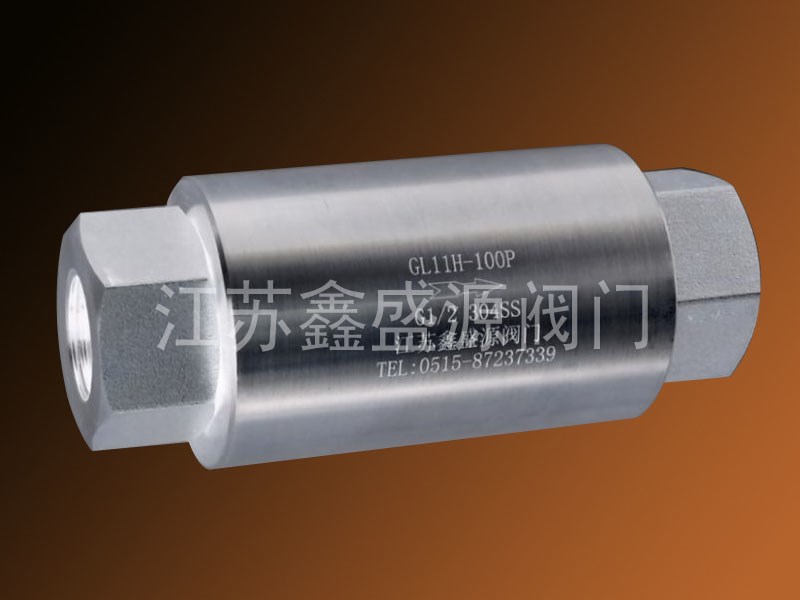

内外螺纹单向阀

商品详情

性能特点

技术参数

内外螺纹单向阀又称为逆流阀、逆止阀、背压阀、单向阀。这类阀门是靠管路中介质本身的流动产生的力而自动开启和关闭的,属于一种自动阀门。止回阀用于管路系统,其主要作用是防止介质倒流、防止泵及其驱动电机机反转,以及容器内介质的泄放。焊接式单向阀只允许介质向一个方向流动,而且阻止方向流动。

公称压力:PN2.5 PN4 PN6.4 PN16 PN40Mpa

公称通径:DN5~DN125

适用介质:油﹑水﹑气等多种非腐蚀性或腐蚀性介质

适用温度:-20℃~+440℃ -70℃~-240℃ ≤540℃ ≤570℃等

制造材料:20#﹑1Cr18Ni9Ti﹑304﹑316﹑316L﹑12Cr1Mov等

内外螺纹单向阀是一种阀体两端分别加工有外螺纹(Male Thread)和内螺纹(Female Thread) 的连接接口的微型或小型止回阀。这种混合螺纹(Combined Thread) 设计提供了极大的安装灵活性,使其能直接适配不同配置的管道系统,而无需额外的转换接头。其核心功能是自动控制流体单向流动,有效防止介质反向倒流,广泛应用于液压、气动、润滑及仪表测量等系统的压力保持与回路保护。

该阀门通常结构紧凑,一端通过外螺纹旋入设备或接头的母口,另一端通过内螺纹与带外螺纹的管道连接。其内部启闭元件多为钢球或锥形阀芯,依靠弹簧力和流体压差实现快速自动启闭。螺纹类型可根据需求定制为公制螺纹(Metric Thread)、美制NPT螺纹(NPT Thread)或英制G螺纹(G Thread)。

内外螺纹单向阀主要特点:

安装灵活便捷: 混合螺纹接口可作为“转换接头”使用,直接连接不同螺纹制式或性别的管路,简化了系统结构,减少了泄漏点。

结构紧凑: 体积小,重量轻,节省安装空间,非常适合在复杂的集成块或设备内部使用。

内外螺纹单向阀密封稳定: 螺纹连接配合密封带或密封胶使用,可形成稳定的密封。

内外螺纹单向阀启闭迅速: 内部结构响应快,有助于减少压力冲击和水锤效应。

内外螺纹单向阀经济稳定: 省去了额外的转接接头和安装成本。

内外螺纹单向阀典型应用:

内外螺纹单向阀液压系统: 集成于液压阀块、油缸的端口,作为背压阀或补油阀。

内外螺纹单向阀气动系统: 连接气缸、电磁阀的接口,控制气流方向。

润滑系统: 用于机械设备润滑油路的单向控制。

仪表测量系统: 安装于压力表、传感器或仪表的接口,防止介质冲击或倒流。

内外螺纹单向阀通用工业设备: 任何需要紧凑型、带转换功能单向阀的场合。

Product Overview of Male & Female Threaded Check Valves

Product Overview:

A Male & Female Threaded Check Valve is a miniature small check valve with external male thread on one end internal female thread on the other end. This combined thread design offers great installation flexibility, allowing it to directly adapt to piping systems with different configurations without the need for additional adapters. Its core function is to automatically control unidirectional fluid flow effectively prevent reverse flow of media. It is widely used for pressure maintenance circuit protection in hydraulic, pneumatic, lubrication, instrumentation systems.

The valve is typically compact. One end is screwed into a female port of equipment a fitting via its male thread, while the other end connects to a male-threaded pipe via its female thread. The internal closing element is usually a ball poppet, which operates automatically via spring force fluid pressure differential. The thread type can be customized as Metric Thread, NPT Thread, G Thread based on requirements.

Key Features:

Flexible & Convenient Installation: The combined threaded ports can act as an "adapter," directly connecting pipes of different thread standards genders, simplifying system structure reducing potential leak points.

Compact Structure: Small size light weight save installation space, making it ideal for use inside complex manifolds equipment.

Reliable Sealing: When used with sealant tape thread sealant, the threaded connection can provide reliable sealing.

Rapid Response: The simple internal structure allows quick opening closing, helping to mitigate pressure shocks water hammer effects.

Cost-Effective: Eliminates the need for additional adapters their associated installation costs.

Typical Applications:

Hydraulic Systems: Integrated into ports of hydraulic manifolds cylinders, serving as a back-pressure make-up valve.

Pneumatic Systems: Connected to interfaces of cylinders solenoid valves to control airflow direction.

Lubrication Systems: Used for unidirectional control in machinery lubrication lines.

Instrumentation Systems: Installed on ports of pressure gauges, sensors, instruments to protect against media impact backflow.

General Industrial Equipment: Any application requiring a compact check valve with built-in adaptation functionality.

关键术语翻译 (Key Terminology Translation):

内外螺纹单向阀: Male & Female Threaded Check Valve / Combination Threaded Check Valve

外螺纹: Male Thread / External Thread

内螺纹: Female Thread / Internal Thread

混合螺纹: Combined Thread

公制螺纹: Metric Thread

NPT螺纹: NPT Thread (National Pipe Taper Thread)

G螺纹: G Thread (Parallel Pipe Thread)

转换接头: Adapter

背压阀: Back-Pressure Valve

补油阀: Make-up Valve