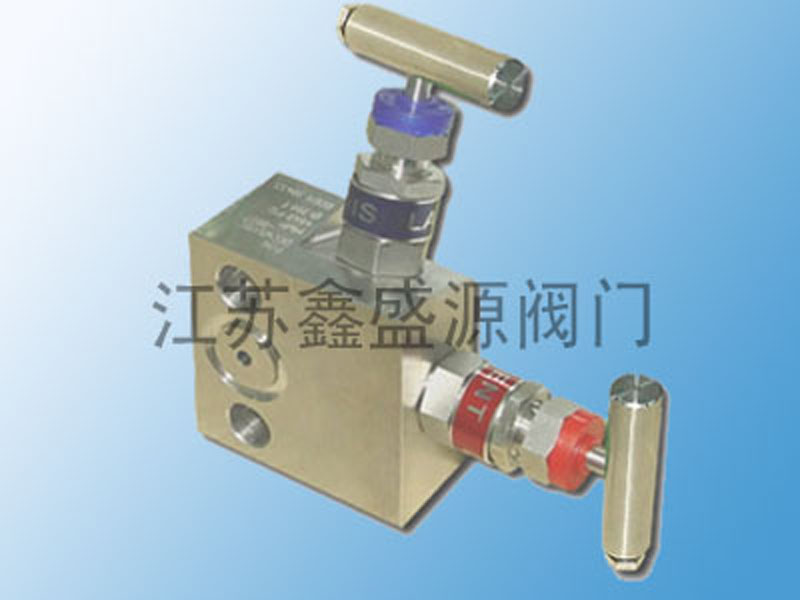

M211W-内螺纹二阀组

商品详情

性能特点

技术参数

产品名称:M211W-内螺纹二阀组

产品型号:M211W SS-M2

所属类别:仪表阀组 >> 两阀组

所属系列:DC

M211W-内螺纹二阀组安装尺寸图

| 订货信息 | ||||

| 代码 | 结构件材料 | |||

| 阀体 | 阀帽 | 阀杆 | 泄放/排污堵头 | |

| 1 | 304SST | 304SST | 304SST | 304SST |

| 2 | 316SST | 316SST | 316SST | 316SST |

| 代码 | 填料 | |||

| 1 | 四氟乙烯 | |||

| 2 | 石墨 | |||

| 代码 | 安装螺栓 | |||

| BA | 与传统型压力变送器直接安装 螺栓孔规格7/16UNF | |||

| BB | 与传统型压力变送器直接安装 螺栓孔规格M10×1.5 | |||

| BC | 与共面法兰型3051C 变送器直接安装 | |||

| BD | 与传统法兰型3051C 变送器直接安装 | |||

| BS | 定制螺栓 | |||

| 代码 | DC阀组选项 | |||

| 安装支架 | ||||

| B4 | 用于2-in.管安装的不锈钢支架 300 不锈钢螺栓,仅适用于阀组类型代码W | |||

| 排污泄放孔及堵头 | ||||

| PG | 带排污孔及堵头,仅适用于T型及H型三阀组 | |||

| 清洗 | ||||

| P2 | 特殊清洗(禁油),仅适用填料为四氟乙烯的场合 | |||

| 接头(用于阀组类型代码W和T) | ||||

| CA | 1/2-14NPTM-Ф14×2对焊接头 | |||

| CB | 1/2-14NPTM-Ф1/2-in卡套接头 | |||

| CC | 1/2-14NPTM-Ф12卡套接头 | |||

| CD | 1/2-14NPTM-Ф6卡套接头 | |||

| CS | 定制接头 | |||

| 转换法兰(用于阀组类型代码H) | ||||

| DF | 1/2-14NPTF 转换法兰 | |||

| DS | 定制法兰 | |||

| 组装 | ||||

| IA | 与仪表一体化组装并打压测试 | |||

M211W-内螺纹二阀组

M211W-内螺纹二阀组是一种紧凑型、集成化的仪表阀门组件,其名称明确指出了其内部螺纹连接方式和双阀结构。它通常由一个压力通道隔离阀(Block Valve) 和一个排污/泄放阀(Bleed Valve) 集成在一个阀体上构成,主要用于压力变送器、压力开关或压力表的安装根部。

M211W-内螺纹二阀组的核心功能是实现对过程管路的安全隔离和介质排放。隔离阀用于切断仪表与过程管道的连接,而排污阀则用于在维护前安全地排放掉阀组与仪表之间截留的介质,或者用于冲洗引压管。这种设计确保了仪表能够在无需工艺停车的情况下进行安全拆卸、校准或维护。

M211W-内螺纹二阀组“M211W”通常是制造商的特定型号代码,用于标识这种特定结构和功能的阀组。其内螺纹连接(如NPT、BSP)方式使其安装紧凑,非常适合直接安装在仪表的入口处,极大减少了安装空间和潜在的泄漏点。

M211W-内螺纹二阀组主要特点:

内螺纹连接: 过程接口和仪表接口通常采用内螺纹,结构紧凑,安装方便。

集成设计: 将隔离和排污功能集成于一个阀体,减少泄漏点。

安全维护: 提供安全的仪表隔离和泄压通道,实现在线维护。

结构紧凑: 体积小巧,适用于空间有限的安装场合。

经济高: 相比单独安装两个阀门,减少了管件和安装成本。

M211W-内螺纹二阀组典型应用:

广泛应用于石油、化工、电力、水处理等行业的压力测量点,作为压力变送器、压力开关或压力表的根部阀,确保测量系统的安全性和可维护性。

M211W Female Threaded 2-Valve Manifold Product Overview

The M211W Female Threaded 2-Valve Manifold is a compact, integrated instrumentation valve package. Its name clearly indicates its female threaded connection style two-valve structure. It typically consists of one block valve (for isolating the pressure channel) one bleed valve (for venting/draining), integrated into a single body. It is primarily used at the root connection for pressure transmitters, pressure switches, pressure gauges.

The core function of this manifold is to provide safe isolation the process line media evacuation. The block valve is used to isolate the instrument the process pipeline, while the bleed valve is used to safely evacuate any trapped media between the manifold the instrument prior to maintenance, for flushing the impulse line. This design ensures that the instrument can be safely removed, calibrated, maintained without requiring a process shutdown.

"M211W" is typically the manufacturer's specific model code for identifying this particular design functionality. Its female threaded connections (e.g., NPT, BSP) allow for a compact installation, making it ideal for mounting directly at the instrument's inlet, significantly reducing the required space potential leak points.

Key Features:

Female Threaded Connections: Process instrument connections are typically female threads, offering a compact structure easy installation.

Integrated Design: Combines isolation bleeding functions into one body, reducing potential leak points.

Safe Maintenance: Provides safe instrument isolation a pressure relief path for in-service maintenance.

Compact Structure: Small size is suitable for installations with limited space.

Cost-Effective: Reduces the need for additional fittings lowers installation costs compared to installing two separate valves.

Typical Applications:

Widely used at pressure measurement points in industries such as oil & gas, chemical, power generation, water treatment. It serves as the root valve for pressure transmitters, pressure switches, pressure gauges, ensuring the safety maintainability of the measurement system.