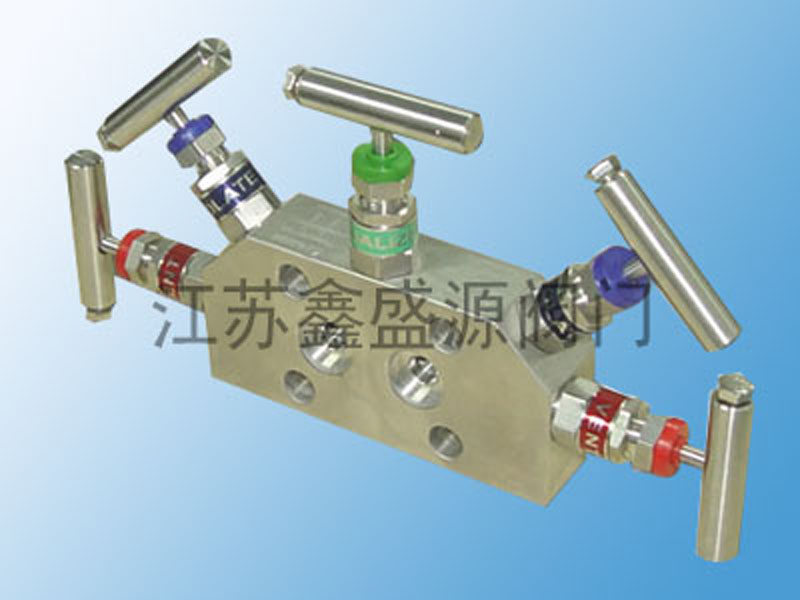

共面取压五阀组

商品详情

性能特点

技术参数

产品名称:共面取压五阀组

产品型号:DRCC5

所属类别:仪表阀组 >> 五阀组

所属系列:DR

安装尺寸图

| 订货信息 | ||||

| 代码 | 结构件材料 | |||

| 阀体 | 阀帽 | 阀杆 | 泄放/排污堵头 | |

| 1 | 304SST | 304SST | 304SST | 304SST |

| 2 | 316SST | 316SST | 316SST | 316SST |

| 代码 | 填料 | |||

| 1 | 四氟乙烯 | |||

| 2 | 石墨 | |||

| 代码 | DR阀组选项 | |||

| 共面型阀组支架 | ||||

| B4 | 用于2-in.管安装的不锈钢支架 300 不锈钢螺栓 | |||

| 清洗 | ||||

| P2 | 特殊清洗(禁油),仅适用填料为四氟乙烯的场合 | |||

| 接头(用于阀组类型代码C) | ||||

| CA | 1/2-14NPTM-Ф14×2对焊接头 | |||

| CB | 1/2-14NPTM-Ф1/2-in卡套接头 | |||

| CC | 1/2-14NPTM-Ф12卡套接头 | |||

| CD | 1/2-14NPTM-Ф6卡套接头 | |||

| CS | 定制接头 | |||

| 接头(用于阀组类型代码T) | ||||

| TA | 1/4-18NPTM-Ф14×2 对焊接头 | |||

| TB | 1/4-18NPTM-Ф1/2-in 卡套接头 | |||

| TC | 1/4-18NPTM-Ф12 卡套接头 | |||

| TD | 1/4-18NPTM-Ф6 卡套接头 | |||

| TS | 定制接头 | |||

| 转换法兰(用于阀组类型代码T) | ||||

| DF | 1/2-14 NPTF 转换法兰 | |||

| DS | 定制法兰 | |||

| 过程法兰连接孔规格(用于阀组类型代码T) | ||||

| HK | M10×1.5 内螺纹 | |||

| 组装 | ||||

| IA | 与仪表一体化组装并打压测试 | |||

共面取压五阀组

共面取压五阀组是一种专为差压式流量测量系统设计的高精度、高性能集成阀组。其核心设计特点是:阀体上与工艺管道连接的两个取压接口(正压和负压)处于同一平面,并且具有确切的间距,旨在与标准孔板法兰、流量喷嘴或其他差压式流量测量元件的取压口实现无应力、精准对口的直接安装。

共面取压五阀组这种设计避免了传统的、独立的引压管连接,极大地减少了安装误差、泄漏点以及由引压管带来的测量滞后、堵塞、积液和气泡等问题,从而明显提高了流量测量的准确性、稳定性和响应速度。

共面取压五阀组主要特点与功能:

共面取压设计: 这是核心的特征。两个取压口中心距严格符合ISO 5167或GB/T 2624等标准规定的孔板法兰间距要求,确保与流量测量元件的取压口准确对准,实现直接安装,消除了安装应力对测量精度的影响。

全功能集成: 集成了五个阀门的功能,通常包括:

两个过程隔离阀: 用于隔离仪表和工艺管道。

一个平衡阀: 用于在投运和停运时保护差压变送器。

两个排污/排气阀: 用于在线排除引压腔内的杂质或气体。

共面取压五阀组提升测量性能:

高精度: 缩短了取压路径,减少了压力在传递过程中的失真和滞后。

快速响应: 几乎无引压管容积,系统响应时间极短,能快速跟踪流量变化。

共面取压五阀组高稳定性: 极大减少了泄漏点和可能堵塞的环节,维护需求低。

共面取压五阀组防止积液/气: 优化的流道设计有助于介质顺利流过,减少了冷凝液或气体在取压腔内的积聚。

简化安装与维护: 整体式结构安装便捷,无需现场配置复杂的引压管和支架,节省了大量安装时间和成本。在线排污和隔离功能也使维护变得简单安全。

共面取压五阀组高标准应用: 主要用于要求高精度流量测量的场合,如天然气贸易计量(Fiscal Metering)、蒸汽流量测量、高性能过程控制以及各类清洁或脏污介质的差压流量测量。

核心优势总结 (Summary of Core Advantages)

传统引压管方式共面取压五阀组多个接头、焊缝,泄漏点多泄漏点极少,一体化结构引压管长,响应慢,易失真响应极快,几乎无信号失真引压管易堵塞、积液、积气有效防止堵塞和积液安装复杂,耗时耗力安装简便快捷,节省成本存在安装应力风险无应力安装,确保精度

Product Overview of a Flush-Faced / Coplanar 5-Valve Manifold

A Flush-Faced 5-Valve Manifold, also known as a Coplanar Pressure Tap Manifold, is a high-precision, high-performance integrated valve assembly specifically designed for differential pressure (DP) flow measurement systems. Its core design feature is that the two pressure tap connections (high-pressure low-pressure) on the valve body are on the same plane (coplanar) have a precise center-to-center distance. This is designed for direct, stress-free, perfectly aligned mounting onto the pressure taps of standard orifice flanges, flow nozzles, other DP primary elements.

This design eliminates the need for traditional, separate impulse piping, greatly reducing installation errors, potential leak points, measurement issues associated with impulse lines such as lag, clogging, liquid accumulation, gas entrapment. Consequently, it significantly enhances the accuracy, stability, response speed of flow measurement.

Key Features Functions:

Coplanar Tap Design: This is the most critical feature. The center distance between the two pressure taps strictly complies with standards like ISO 5167 GB/T 2624 for orifice flanges, ensuring perfect alignment with the primary element's taps for direct mounting. This eliminates measurement errors caused by installation stress.

Full-Function Integration: It incorporates the functions of five valves, typically including:

Two Process Block Valves: For isolating the instrument the process pipeline.

One Equalizing Valve: For protecting the DP transmitter during commissioning decommissioning.

Two Vent/Drain Valves: For online purging of contaminants gases the pressure chambers.

Enhanced Measurement Performance:

High Accuracy: Shortens the pressure transmission path, minimizing pressure signal distortion lag.

Fast Response: Minimal system volume due to the lack of impulse tubing allows for extremely short response times, enabling quick tracking of flow changes.

High Reliability: Dramatically reduces potential leak points clogging opportunities, lowering maintenance requirements.

Prevents Accumulation: Optimized flow channel design helps media flow through, reducing the buildup of condensate gas in the pressure chambers.

Simplified Installation Maintenance: The unitary structure allows for easy installation, eliminating the need for complex field-run impulse piping supports, which saves significant installation time cost. Online blowdown isolation features also make maintenance simple safe.

High-Standard Application: Primarily used in applications demanding high-precision flow measurement, such as natural gas fiscal metering, steam flow measurement, high-performance process control, various DP flow measurements for clean dirty media.