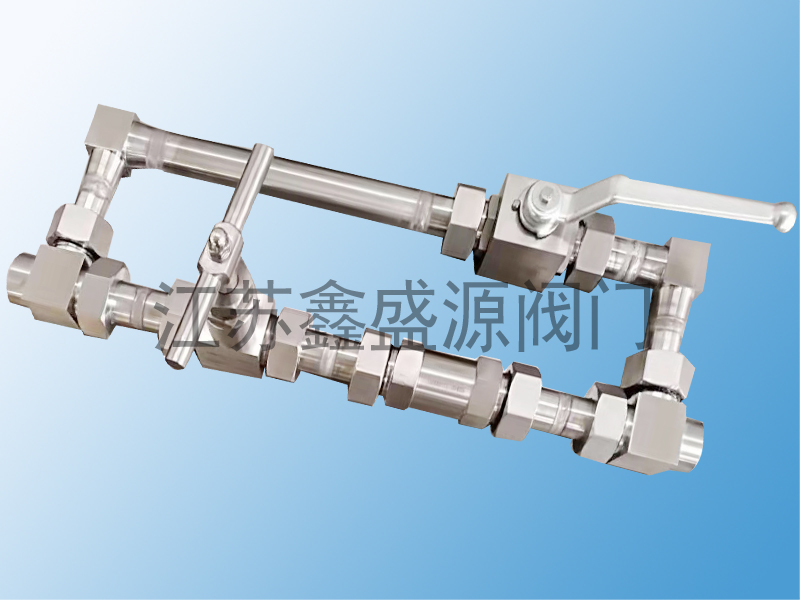

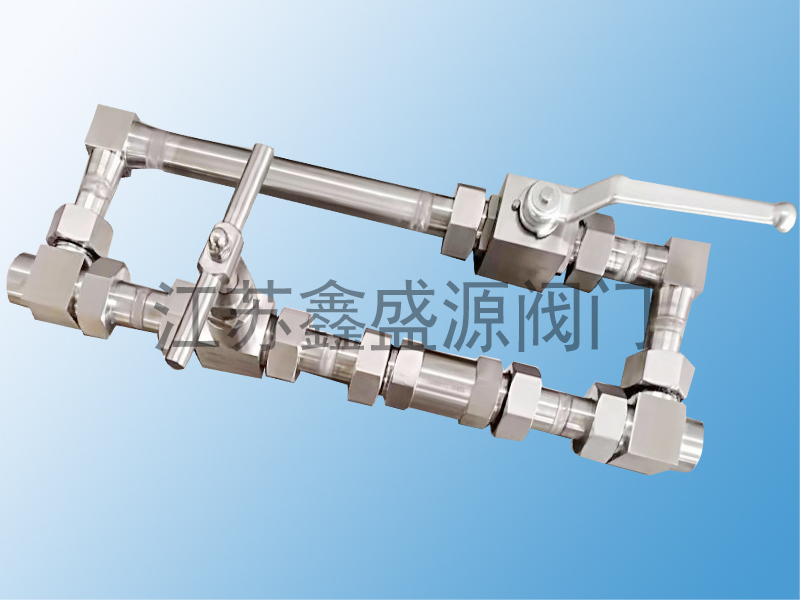

进气/油集成装置

商品详情

性能特点

技术参数

进气/油集成装置

进气/油集成装置

进气/油集成装置是一种高度集成化的发动机核心子系统。它将原本分散的进气部件(如进气管、节气门体、进气歧管)和燃油部件(如燃油轨、喷油器)等整合在一个紧凑的模块中。

进气/油集成装置其主要目的是通过优化结构布局,实现发动机性能的提升。它能够:

· 进气/油集成装置提升发动机响应与动力输出:通过优化进气气流和燃油雾化效果,使空气与燃油在进入燃烧室前实现迅捷混合,从而提升燃烧效率,使发动机获得更强劲的动力。

· 进气/油集成装置减少污染排放:更充分的燃烧有助于降低尾气中有害物质的排放。

· 进气/油集成装置优化空间布局与降低成本:集成化设计减少了复杂的独立管路连接,使发动机结构更紧凑,空间利用率更高,同时也降低了制造成本。以美国Delphi公司的概念样机为例,该产品通过彻底整合进气系统和燃料系统的外围零部件,展示了降低成本和提高性能的可能性。

进气/油集成装置主要设计与特点

· 模块化集成设计:

· 将油轨水平安装在集成腔室外侧,喷油器输出端则与腔室接通,输入端与油轨固定接通。

· 采用集成底板或类似结构,将多个增压器的进回油管路进行简化布置。

· 迅捷油气混合:配合燃油轨高压多点雾状喷射燃油,喷油器将来自油轨的汽油雾化喷入腔室与空气混合,使空气和燃油在进入燃烧室前在缸体内迅捷混合。

· 精准进气控制:集成腔室的进气端通常安装有由电机总成控制的可旋转阀片(如节气门),用以控制进入各气缸的进气量。

· 紧凑结构与轻量化:此类集成装置结构紧凑,常采用铝合金等轻质材料制作,有助于减轻整体重量。

进气/油集成装置主要技术参数

下面的表格列出了典型的技术参数(请注意,具体数值会因具体型号、制造商和应用场景而有很大差异):

项目 参数/描述

适用发动机类型 多缸发动机(如直列六缸、两缸等)

进气控制方式 电机驱动的节气门阀片

燃油喷射方式 多点顺序燃油喷射

集成传感器类型 气体压力温度传感器、空气流量传感器等

主要构成部件 包括进气歧管、油轨、喷油器、节气门阀体、气体压力温度传感器等

进气/油集成装置主要材料 铝合金(用于阀体、腔室等结构件)、各类工程塑料或复合材料(用于进气管道)

进气/油集成装置核心组件详解

以下是该集成装置通常包含的主要部件及其功能:

序号 组件名称 功能描述

1 进气总成/进气歧管 将新鲜空气均匀分配到各个气缸。部分设计会将空气流量传感器与连接空气过滤器部和进气集合管部的空气管连为一体。

2 节气门阀体 通过控制阀片旋转来调节进入发动机的总进气量。

3 燃油轨 恒定压力地向各缸喷油器供应燃油。

4 喷油器 根据发动机控制单元指令,将燃油雾化喷入进气歧管或气缸。

5 气体压力/温度传感器 实时监测进气歧管内的压力和温度参数,为发动机控制单元提供修正喷油和点火的依据。

6 集成式壳体/腔室 构成装置的主体,提供各部件的安装基础并形成进气通道。

Product Overview of Intake Fuel Integration Device

The Intake Fuel Integration Device is a highly integrated core subsystem of an engine. It consolidates originally dispersed intake components (such as intake pipes, throttle bodies, intake manifolds) fuel components (such as fuel rails injectors) into a compact module.

Its primary purpose is to enhance engine performance through optimized structural layout. It achieves this by:

· Improving Engine Response Power Output: By optimizing intake airflow fuel atomization, it enables air fuel to mix efficiently before entering the combustion chamber. This improves combustion efficiency, allowing the engine to deliver more powerful performance.

· Reducing Pollutant Emissions: More complete combustion helps lower the emission of harmful substances in the exhaust gases.

· Optimizing Space Layout Reducing Costs: The integrated design reduces complex independent piping connections, resulting in a more compact engine structure, higher space utilization, lower manufacturing costs. Taking the concept prototype Delphi USA as an example, this product demonstrated the potential for cost reduction performance improvement by thoroughly integrating peripheral components of the intake system fuel system.

Design Features

· Modular Integrated Design:

· The fuel rail is mounted horizontally on the outside of the integrated chamber, with the fuel injector's output end connected to the chamber its input end fixed to the fuel rail.

· An integrated baseplate similar structure is used to simplify the layout of oil inlet return lines for multiple turbochargers.

· Efficient Air-Fuel Mixing: Working in conjunction with the fuel rail's high-pressure, multi-point mist-like fuel injection, the injectors spray atomized fuel into the chamber to mix with air, ensuring efficient mixing of air fuel before they enter the combustion chamber.

· Precise Air Intake Control: The intake end of the integrated chamber typically houses a rotatable valve plate (e.g., a throttle valve) controlled by an electric motor assembly, which precisely regulates the intake air volume entering each cylinder.

· Compact Structure Lightweight: Such integrated devices are compact in structure often manufactured using lightweight materials like aluminum alloy to help reduce overall weight.

Main Technical Parameters

The table below lists typical technical parameters (Please note that specific values can vary significantly depending on the model, manufacturer, application):

Item Parameter/Description

Applicable Engine Type Multi-cylinder engines (e.g., inline-six, two-cylinder, etc.)

Air Intake Control Method Electric motor-driven throttle valve plate

Fuel Injection Method Multi-point sequential fuel injection

Integrated Sensor Types Gas Pressure/Temperature Sensor, Air Flow Sensor, etc.

Main Components Include Intake Manifold, Fuel Rail, Fuel Injector, Throttle Valve Body, Gas Pressure/Temperature Sensor, etc.

Main Materials Aluminum Alloy (for structural parts like valve bodies chambers), various engineering plastics composites (for intake pipes)

Core Components Detailed

The following are the main components typically included in this integrated device their functions:

No. Component Name Functional Description

1 Intake Assembly/Intake Manifold Distributes fresh air evenly to each cylinder. Some designs integrate the Air Flow Sensor with the air pipe connecting the air filter assembly the intake manifold assembly.

2 Throttle Valve Body Precisely regulates the total intake air volume entering the engine by controlling the rotation of the valve plate.

3 Fuel Rail Supplies fuel at constant pressure to the fuel injectors for each cylinder.

4 Fuel Injector Sprays atomized fuel into the intake manifold cylinder based on commands the Engine Control Unit.

5 Gas Pressure/Temperature Sensor Monitors real-time pressure temperature parameters within the intake manifold, providing data for the Engine Control Unit to adjust fuel injection ignition timing.

6 Integrated Housing/Chamber Forms the main body of the device, providing the mounting foundation for components forming the intake passage.